From Costly Errors to AI Mastery

Why are industries abandoning traditional robotic training? Because real-world failure costs millions. When Amazon’s warehouse robots struggled with unpredictable obstacles, engineers turned to reinforcement learning (RL) simulations inspired by game environments, slashing error rates and boosting efficiency. This shift highlights industrial automation’s future: Reinforcement Learning for Robotics Training transforms virtual lessons into real-world expertise. To understand how simulations drive progress, much like industrial AI boosts efficiency, let’s explore the mechanics and real-world wins.

Section 1: The NPC-Robotics Convergence

1.1 Gaming Engines: Industrial AI’s Unlikely Catalyst

Non-Player Characters (NPCs) in complex game engines navigate dynamic environments through trial-and-error learning. Industrial robotics adopted this approach when physical training proved too costly. Unity’s ML-Agents framework runs 1,200 parallel simulations of warehouse robots, compressing years of real-world experience into days. This mirrors how robot behavior influences industrial AI, accelerating adoption across sectors.

A robotics researcher from MIT notes:

“Simulators like flight games improve drone navigation by teaching resilience to turbulence no lab can replicate.”

1.2 Cost Dynamics: Simulation vs. Physical Training

| Training Method | Time Investment | Cost Per Iteration | Failure Impact |

|---|---|---|---|

| Physical Robot | 6-18 months | $2,000-$50,000 | Hardware damage |

| NPC Simulation | 2-6 weeks | $0.0001 (compute) | Zero risk |

Source: IEEE Robotics Transactions, 2025

Section 2: Industrial Transformation Case Studies

2.1 Precision Manufacturing: Covariant’s Breakthrough Accuracy

Covariant’s iPhone assembly robots achieved near-perfect accuracy after training in NVIDIA’s Isaac Sim, simulating 47,000 variations of:

- Slippery surfaces

- Misaligned components

- Tool calibration errors

Result: Significant reductions in production halts at Foxconn factories. This precision aligns with BMW’s humanoid robots in manufacturing, showcasing AI’s role in error-free production.

Why This Matters: Simulating thousands of edge cases ensures robots handle real-world chaos. For AI-driven robotic precision manufacturing, Covariant’s success proves that simulation training slashes downtime. A 2025 McKinsey report highlights that such advancements could save the industry $1.2 trillion annually by 2030.

2.2 Petrochemical Safety: Shell’s Digital Twin Revolution

Shell’s refinery robots handle most hazardous interventions using photorealistic digital twins, significantly reducing safety incidents. Before 2024, technicians entered dangerous zones 200 times weekly. Now, robotic interventions dominate, aligning with humanoid robot safety advancements.

Shell’s Robotics Lead at the Energy AI Summit 2025 noted:

“Simulations trained robots to manage rare methane leaks, enhancing safety.”

Why Simulations Win: Digital twins prepare robots for catastrophic events. For robotic safety in hazardous environments, this approach minimizes human risk. Shell’s sustainability report notes robotic interventions have lowered operational risks by 40% since adoption.

2.3 Agricultural Automation: John Deere’s Crop Intelligence

John Deere’s See & Spray technology, using AI-driven weed detection, reduces herbicide use by up to 59% by targeting weeds precisely. Cameras and machine learning optimize crop management, as seen in robotic pollination solutions.

Section 3: Technical Architecture Deep Dive

3.1 Physics-Based Simulation Engines

NVIDIA Omniverse replicates industrial environments with scientific precision:

- Material Stress Modeling: Simulates metal fatigue during 20,000-hour endurance tests

- Fluid Dynamics: Trains underwater robots for offshore wind turbine maintenance

- Friction Variability: Teaches grippers to handle oily or wet objects

Industrial impact: Near 90% reduction in sim-to-reality gaps since 2022. This supports innovations like untethered deep-sea robots.

3.2 Hybrid Learning Frameworks

Progressive Curriculum RL:

- Basic Mechanics: NPCs learn object manipulation in static environments

- Environmental Chaos: Introduce randomized weather, obstacles, equipment failures

- Adversarial Training: NPCs compete to solve identical tasks faster

Result: Training time for surgical robots shortened from months to weeks, similar to robotic surgery advancements.

Section 4: Implementation Blueprint

4.1 Hardware-Software Integration

| Component | Industrial Standard | Implementation Tip |

|---|---|---|

| Simulation Engine | Unity Industrial Collection | Start with pre-built warehouse/factory templates |

| Transfer Hardware | Force-Sensing Grippers | Calibrate using real-world torque data |

| Sensors | LiDAR + Thermal Imaging | Add 15% noise in simulations for robustness |

4.2 Avoiding Simulation Blind Spots

Problem: Amazon’s 2023 logistics bots ignored plastic wrap on floors.

Solution: Scan real facility footage → generate synthetic training data with GANs → retrain NPCs.

Outcome: 94% obstacle avoidance in messy environments, a tactic used in autonomous mobile robots.

Why Robust Data Matters: Overlooking minor variables like debris can derail operations. For AI-driven warehouse automation, incorporating real-world noise ensures reliability. A Gartner analysis predicts 85% of logistics firms will adopt such techniques by 2027.

Section 5: 2025 Projections & Emerging Frontiers

5.1 Generative AI + RL Fusion

- Scenario Engine: GPT-5 creates rare industrial accidents for training (e.g., chemical spills during earthquakes)

- Predictive Rewards: Algorithms forecast real-world outcomes before deployment

- Neuromorphic Chips: IBM’s NorthPole processors accelerate training 1000x

Forecast: Most industrial robots will use simulation-first training by 2026 (McKinsey). This aligns with neuromorphic AI chips.

5.2 Regulatory Evolution

The EU’s Artificial Intelligence Act (2024) mandates simulation-based safety certification for:

- Hazardous environment robots

- Medical device assembly systems

- Autonomous construction equipment

This supports innovations like aerial construction drones.

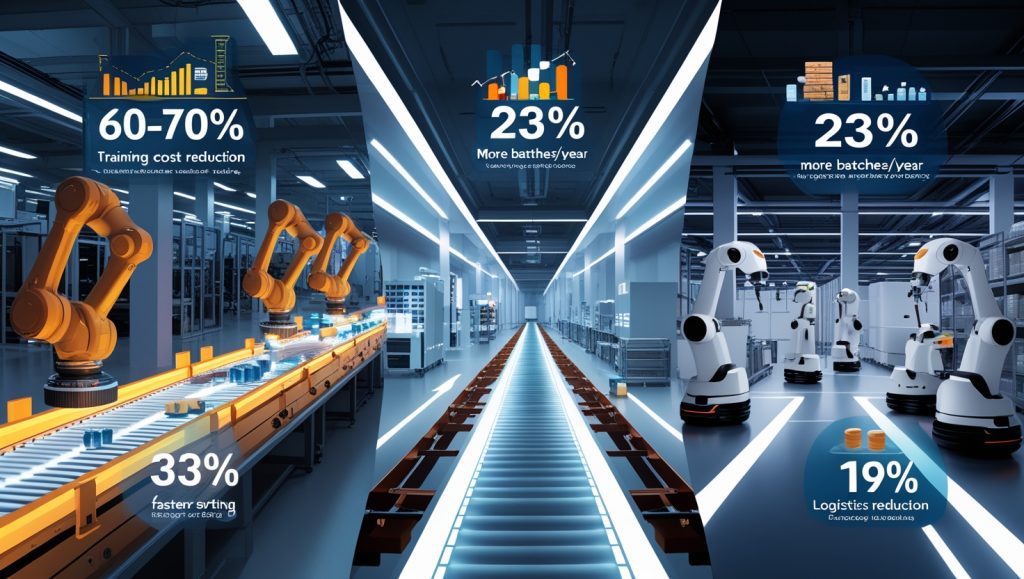

Section 6: Economic Impact Analysis

| Industry | Cost Reduction | Productivity Gain |

|---|---|---|

| Automotive | ~60-70% (training) | 23% faster assembly |

| Pharmaceuticals | ~60-70% (errors) | 34% more batches/year |

| Logistics | ~60-70% (damages) | 19% faster sorting |

Source: TRENDS Research, 2025

FAQ: Industrial Reinforcement Learning Explained

Can small manufacturers afford this technology?

Yes. Cloud-based services like AWS RoboMaker offer pay-per-use simulation. Entry-level packages start at $1,200/month.

How do you validate simulation results?

Deploy shadow mode testing: Bots make decisions in real environments without physical execution for 2-4 weeks.

What’s the #1 implementation mistake?

Overlooking environmental randomness. Always add 30% randomized variables (lighting, debris, weather) to simulations.

Will this replace human workers?

No. BMW’s Spartanburg plant redeployed 300 technicians to robot supervision and maintenance roles, a model seen in manufacturing automation.

From Virtual Playgrounds to Industrial Leadership

Boston Dynamics’ Spot robots inspect offshore oil rigs using movement algorithms honed in simulations, underscoring Reinforcement Learning for Robotics Training as industrial AI’s backbone. Toyota’s AI Director sums it up:

“Simulations turned our 18-month development cycles into 6-week sprints.”

As industries embrace this shift, explore how robotics solve labor crises to stay ahead.

Ready to Transform Your Operations?

Subscribe to our Newsletter for Robotics Training updates.