What if the factories of the future aren’t on Earth but in the vast expanse of space? In 2025, Zero-Gravity Robotic Manufacturing is shifting from theoretical marvel to industrial reality. This article dives deep into seven groundbreaking innovations redefining how humanity builds beyond Earth—solving urgent challenges like space debris, lunar colonization, and resource scarcity. Backed by real-world missions, expert insights, and actionable data, we unravel why Zero-Gravity Robotic Manufacturing isn’t just revolutionary—it’s essential for our survival.

Why Zero-Gravity Manufacturing Is Humanity’s Next Industrial Leap

The International Space Station (ISS) recycles 90% of its water. NASA’s Artemis Program aims to establish a lunar base by 2030. SpaceX’s Starship plans to ferry materials to Mars. Behind these headlines lies a silent disruptor: Zero-Gravity Robotic Manufacturing.

Unlike Earth, space lacks gravity, atmosphere, and human-friendly conditions. This forces engineers to rethink manufacturing from scratch. “In space, you can’t just bolt parts together. You need systems that adapt to chaos,” explains Dr. Michelle Parker, a NASA lead engineer. Zero-Gravity Robotic Manufacturing leverages orbital robotics to create structures and tools in microgravity, enabling feats impossible on Earth, like assembling massive solar arrays or printing habitats from lunar soil.

The Three Urgent Challenges Driving Innovation

- Space Debris Crisis: Over 36,000 objects larger than 10 cm orbit Earth, threatening satellites worth $1 trillion.

- Lunar Ambitions: NASA’s Artemis Program requires in-situ resource utilization (ISRU) to avoid $1 million/kg launch costs.

- Earth’s Resource Limits: Rare minerals for tech are dwindling; asteroid mining could offset this—if we can process materials in orbit using Zero-Gravity Robotic Manufacturing.

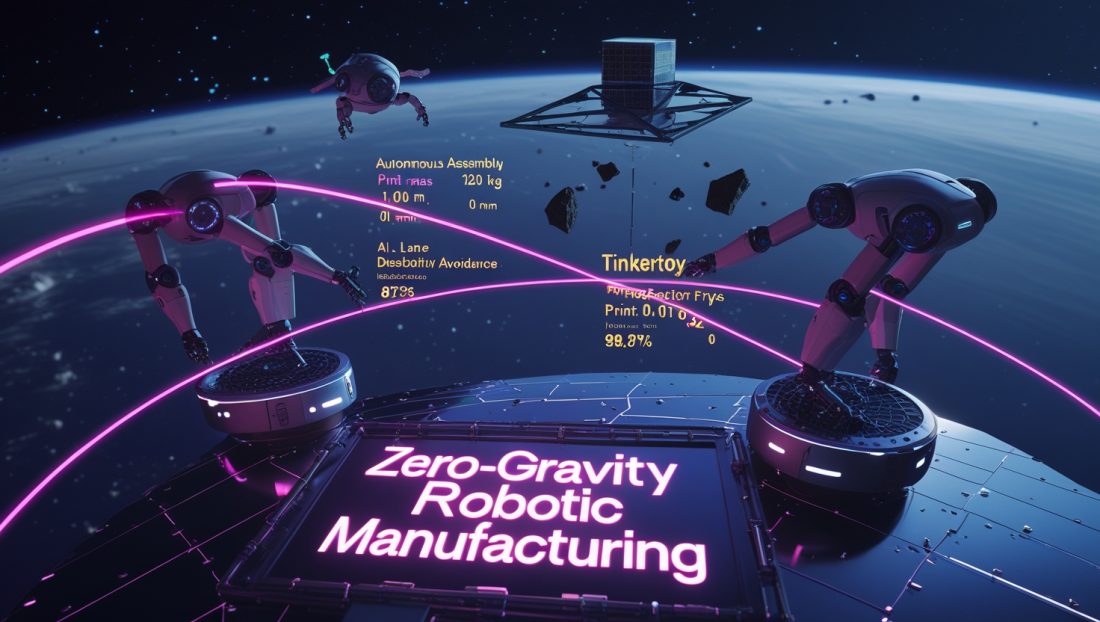

Breakthrough 1: Autonomous Orbital Assembly – LEGO for Space Engineers

From Theory to Reality: Caltech’s 2026 Tinkertoy Experiment

In February 2026, Caltech and Momentus Inc. will launch Project CosmicWeaver, a free-flying robotic system designed to autonomously assemble a 1.4-meter truss in low-Earth orbit (LEO). Using carbon-fiber rods and gecko-inspired adhesive grippers, the robots mimic children’s Tinkertoys—snapping parts into frameworks for solar arrays or antennas. This leap in Zero-Gravity Robotic Manufacturing showcases how space manufacturing can transform satellite construction. The project builds on prior successes in autonomous systems, like those explored in Why Autonomous Mobile Robots (AMRs) Are Dominating, where self-navigating robots revolutionized terrestrial logistics. In space, these principles scale to handle the chaos of microgravity, ensuring precision in orbital robotics.

Why This Matters

Traditional satellite launches require rigid, pre-built structures. CosmicWeaver slashes payload mass by 60%, allowing larger infrastructures like next-gen communication grids for lunar missions. The system’s AI navigates microgravity challenges, such as floating debris and thermal fluctuations, using real-time lidar mapping. This innovation in Zero-Gravity Robotic Manufacturing paves the way for scalable in-space production.

“This isn’t just assembly—it’s evolution. Imagine satellites that self-repair or expand post-launch,” says Dr. Carlos Hernandez, Caltech’s project lead.

Case Study: Zero-G Lab’s Real-World Testing

In 2024, a prototype robot at the Zero-G Laboratory (ZGLAB) successfully docked with a mock satellite, though a collision with foam debris highlighted algorithmic gaps. “Failures here save millions in orbit,” notes ZGLAB’s director. These tests refine the AI driving Zero-Gravity Robotic Manufacturing, ensuring orbital robotics can handle real-world challenges like debris navigation. Like How Autonomous Robots Are Redefining Space Construction

Breakthrough 2: 3D Printing Beyond Gravity – From Resins to Moon Dust

Photocentric’s CosmicMaker: A Printer for the Void

UK-based Photocentric stunned engineers in 2024 by adapting its 3D printers for Zero-Gravity Robotic Manufacturing. The CosmicMaker uses UV-cured resins to produce ISS spare parts with 0.01mm precision, reducing resupply missions by 40%. This technology aligns with advancements in Robotics in 3D Printing, where precision printing reshapes industries. In space, the CosmicMaker’s ability to operate in microgravity makes it a cornerstone of in-space production, enabling on-demand manufacturing of critical components without costly Earth launches.

Lunar Ambitions: DARPA’s NOM4D Program

DARPA’s 2025 initiative tests printing with lunar regolith simulants. Early prototypes created radiation-shielded wall segments, critical for Artemis’ planned Moon base. “By 2030, we’ll print habitats using Moon dirt,” claims Andrew Detor, NOM4D Program Manager. This application of Zero-Gravity Robotic Manufacturing reduces dependency on Earth resources.

Terrestrial Spin-Offs: Earth’s Rapid Construction

Japan’s Kotai robot 3D-printed a train station in 3 hours using Martian soil simulants—proving rapid construction for disaster zones. These terrestrial applications highlight the versatility of Zero-Gravity Robotic Manufacturing techniques. Check out NASA’s In-Space Manufacturing Initiatives

Breakthrough 3: Floating Labs – Earth’s Testing Grounds for Cosmic Factories

Zero-G Laboratory: Where Robots Learn to “Swim”

Before reaching orbit, robots train at facilities like Colorado’s ZGLAB, a hub for refining Zero-Gravity Robotic Manufacturing. Air-bearing tables mimic microgravity, letting engineers test SIL (Software-in-the-Loop) systems. A Raspberry Pi-powered bot recently autonomously docked with a tumbling satellite model—a leap for debris-clearing missions. This mirrors advancements in Robot Dog Navigation Rescue, where AI-driven robots navigate complex environments. At ZGLAB, these tests ensure orbital robotics can handle the unpredictability of space, making Zero-Gravity Robotic Manufacturing more reliable.

Cost vs. Reward

Lab tests cost ~$500k, versus $50 million for orbital failures. “Every hour here prevents a decade of setbacks,” says ZGLAB engineer Mara Lin.

A Technician’s Tale

“During a 2024 trial, a bot misjudged a grab and spun wildly. We laughed, then redesigned its sensors,” recalls a technician.

Breakthrough 4: Soft Robotics – Prosthetic Hands and Asteroid Miners

Johns Hopkins’ Hybrid Hand: Space Tech Saving Lives

Johns Hopkins’ 2025 robotic hand blends 3D-printed PLA bones with silicone muscles. Designed for astronauts, its 98.38% texture recognition accuracy now aids amputees. “Space constraints bred innovation,” says lead designer Dr. Elena Torres. This innovation ties to Soft Humanoid Robots Home Safety, where soft robotics enhance human-robot interaction. In Zero-Gravity Robotic Manufacturing, such technologies enable delicate tasks like assembling intricate components in space.

ETH Zurich’s SpaceHopper: The Asteroid Hopper

This three-legged robot uses AI to navigate asteroid surfaces, sampling minerals in low gravity. “Asteroids hold platinum, gold—enough to collapse Earth’s markets if mined responsibly,” says ETH’s Fabio Buhler. Check out ESA’s Parabolic Flight Experiments

Breakthrough 5: Sustainable Orbital Factories – Recycling in the Void

GRAVI-BOT: Purdue’s Microgravity Centrifuge

Purdue’s 2024 GRAVI-BOT uses compressed air to separate alloys in zero-g, enabling in-space recycling. Meanwhile, NASA’s Astrobee robots on the ISS prototype tools to repurpose debris into raw materials. This aligns with Robotics in Recycling, where robots streamline waste processing. In Zero-Gravity Robotic Manufacturing, recycling debris into usable materials reduces space junk and supports sustainable space manufacturing.

Stat Alert: Closed-Loop Inspiration

The ISS’s 90% water recycling rate inspires closed-loop space factories. Check out The Future of Space Sustainability

Breakthrough 6: AI-Driven Quality Control – Machines Watching Machines

MIT’s Neural Network for Flaw Detection

MIT’s 2025 algorithm analyzes 3D-printed parts in real-time, detecting microfractures invisible to humans. Tested on the ISS, it reduced part failures by 33%. This technology complements AI in Robotics, where AI enhances precision but faces challenges. In Zero-Gravity Robotic Manufacturing, such algorithms ensure the reliability of in-space production, critical for long-term missions.

Cosmic Supervision

“AI isn’t replacing engineers—it’s making them cosmic supervisors,” argues MIT’s Dr. Raj Patel.

Breakthrough 7: Crowdsourced Space Tech – Raspberry Pi in Orbit

Democratizing Access: $500 Robots in Zero-G

Open-source projects like PiCosmos let universities test microgravity robots for under $500. “We’re empowering the next Elon Musks,” says PiCosmos founder Liam Chen. This democratization echoes STEM Robotics Competitions, which inspire innovation. By lowering barriers, Zero-Gravity Robotic Manufacturing becomes accessible, accelerating advancements in space manufacturing.

FAQs: Addressing Public Curiosity

How much does Zero-Gravity Robotic Manufacturing cost?

Orbital projects average $10M–$50M, but terrestrial simulations (e.g., ZGLAB) cost 1,000x less.

Can this tech help Earth’s climate crisis?

Yes. Space-based solar farms (built via Zero-Gravity Robotic Manufacturing) could provide limitless clean energy.

Is asteroid mining feasible by 2030?

Likely not before 2040 due to legal/technical hurdles, but prototypes like SpaceHopper are paving the way.

Building Tomorrow’s Infrastructure – Beyond Earth

Zero-Gravity Robotic Manufacturing isn’t just about tools—it’s about reimagining humanity’s place in the cosmos. By 2030, this $10B industry could cut launch costs by 70% and make lunar bases routine. As Dr. Parker notes, “We’re not just building machines—we’re building a multiplanetary species.”

CTA: Ready to witness the future? Subscribe for Monthly Space Tech Updates