A Political Promise vs. Silicon Valley’s Reality

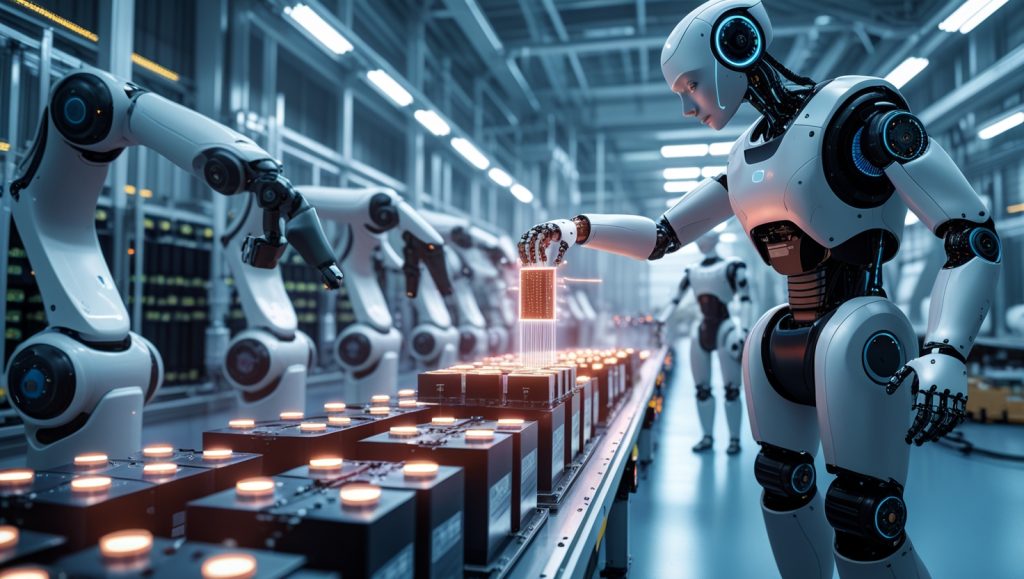

What happens when political pledges to “bring back jobs” collide with a future dominated by robots? As Donald Trump renews his push to revive U.S. manufacturing automation jobs ahead of the 2025 election, his tech allies—Elon Musk, Jeff Bezos, and Jensen Huang—are investing billions in automation. This clash between nostalgia for factory floors and Silicon Valley’s efficiency-driven vision is reshaping America’s economic landscape. For a deeper look at how companies like Nvidia are pushing the boundaries of automation, explore cloud-connected humanoid robots revolutionizing manufacturing.

The Reshoring Boom: Factories Return, but Workers Don’t

In 2025, the U.S. is projected to add 350,000 new manufacturing facilities, driven by Trump-era tariffs and incentives like the CHIPS Act. However, these factories increasingly rely on robots, not human labor. Tesla’s Texas Gigafactory, for instance, operates with 75% automation, producing 500,000 EVs annually with just 5,000 workers. This shift highlights the growing demand for manufacturing automation jobs, where skilled technicians oversee robotic systems rather than traditional assembly roles. To understand how automation is transforming other industries, check out energy-efficient robotics trends shaping 2025.

The Automation Tipping Point

Automation adoption surged after pandemic-era supply chain shocks. Companies like Ford and General Motors now prioritize AI-driven systems to mitigate labor shortages. A 2025 National Association of Manufacturers report revealed that 63% of U.S. factories plan to automate 50% of tasks by 2026, creating new opportunities in manufacturing automation jobs for those trained in robotics oversight. MIT economist David Autor notes, “The factories are coming back, but the jobs aren’t the same. Automation allows reshoring, but it decouples production from employment.” For insights into how automation is reshaping global supply chains, see Switzerland’s autonomous delivery robots tackling logistics challenges.

Why Tech Titans Bet on Robots Over Workers

Labor Economics and Global Pressure

The U.S. faces a shortfall of 2.1 million manufacturing workers by 2030. With wages rising 18% since 2020, companies like Hyundai and Nvidia view robots as a hedge against labor costs. Hyundai’s $21 billion Georgia plant uses autonomous mobile robots (AMRs) to reduce assembly time by 30%, boosting demand for manufacturing automation jobs focused on programming and maintenance. Learn more about why AMRs are dominating modern factories.

Geopolitical Strategy

China’s dominance in robotics—producing 45% of industrial robots globally—forces U.S. firms to automate or fall behind. The Pentagon’s 2025 National Defense Industrial Strategy explicitly links automation to supply chain resilience, urging companies to adopt AI-driven systems to secure manufacturing automation jobs. For a look at China’s robotic advancements, read about China’s industrial robot dominance reshaping global manufacturing.

Tech Allies’ Influence and the Rise of Humanoid Robots

Elon Musk’s Tesla Optimus robots, priced at $20,000 each, promise to replace repetitive tasks in factories, creating new manufacturing automation jobs for robot calibration and supervision. Meanwhile, Jeff Bezos’ $100 million investment in Agility Robotics targets warehouse automation, claiming bots can reduce logistics costs by 40%. This shift is sparking debates about the role of humanoids in industry, as explored in why humanoid robots are both unsettling and revolutionary.

Case Study: The Electric Vehicle Industry’s Automation Surge

The EV sector exemplifies the tension between job creation and automation. While the Biden and Trump administrations poured $50 billion into domestic battery production, companies like Panasonic and LG Energy Solution deploy robots for 90% of cell manufacturing, driving demand for manufacturing automation jobs in quality control and system management.

- Tesla’s Fremont Facility: Employs 1,200 robots per 10,000 tasks, up from 800 in 2020.

- GM’s Ultium Battery Plants: Use AI-powered quality control systems, reducing human inspectors by 70%.

Worker Displacement:

In Lordstown, Ohio, GM’s shift to automated EV production led to 1,600 layoffs in 2023. Former assembly line worker Maria Gonzalez told The Washington Post: “They promised new jobs, but the robots took them.” This trend underscores the need for upskilling in manufacturing automation jobs. For a broader perspective, see how BMW’s humanoid robots are enhancing precision manufacturing.

The Skills Gap: Can Workers Adapt?

The White House touts “robot maintenance technician” roles paying $85,000 annually, but retraining lags. Only 12% of displaced manufacturing workers enroll in STEM programs, per a 2025 Brookings Institution study. Community colleges like Georgia Tech now offer robotics certifications, yet enrollment remains below demand for manufacturing automation jobs. To get started in this field, check out how to build your first robot.

Union Responses and Workforce Retraining

The United Auto Workers (UAW) negotiated contracts requiring automakers to retrain workers for automation oversight. However, Trump’s 2025 opposition to “union mandates” threatens such agreements. For insights into how robotics education is shaping future workers, explore why STEM robotics competitions are fueling innovation.

Policy Crossroads: Tariffs, Taxes, and Tech

Trump’s proposed 10% universal tariff aims to boost domestic production, but economists warn it could accelerate automation, creating more manufacturing automation jobs while reducing traditional roles. A 2025 Peterson Institute analysis estimates tariffs would incentivize 25% more robot adoption by 2030.

Contrasting Visions for America’s Industrial Future

- Trump’s Model: Tax breaks for reshoring, reduced regulations, and skepticism of climate-linked subsidies.

- Biden’s Legacy: $2 trillion in green manufacturing incentives tied to job creation quotas.

For a deeper dive into how automation intersects with sustainability, read about why robotics in recycling is reshaping global waste management.

Human Stories Behind the Automation Wave

(Fictional Anecdote)

James, a 45-year-old machinist in Detroit, spent six months retraining as a robotics technician. “I’m grateful for the job, but half my team didn’t make the cut,” he says. “We need policies that don’t leave people behind.” His story reflects the broader challenge of transitioning to manufacturing automation jobs. For more on how automation impacts workers, see why robots are solving the labor crisis and what stops them.

Global Lessons: How Other Nations Navigate Automation

Germany’s Mittelstand Model: Balancing Robots and Workers

Germany combines automation with apprenticeships—85% of manufacturers train workers in robotics, ensuring a steady pipeline of manufacturing automation jobs.

South Korea’s Tax Incentives: Retaining Human Talent

South Korea offers subsidies for companies that automate while retaining 90% of staff, a model that supports both innovation and employment.

For a global perspective, explore why China’s robot rentals are sparking a labor revolution.

The Path Forward: A Blueprint for Balanced Growth

- Expand the Pell Grant Program to cover robotics certifications.

- Tax Incentives for Hybrid Workforces: Reward companies that employ humans alongside robots.

- National Automation Safety Standards: Prevent exploitative “dark factories” with zero workers.

For more on how automation can align with human welfare, read about why robotics is the secret weapon in the fight against climate change.

FAQ: Addressing Common Concerns

Will automation lower wages?

Studies show mixed results. While tech jobs pay more, displaced workers often face income drops.

Which industries will automation hit hardest?

Automotive, electronics, and textiles are most vulnerable.

Can small manufacturers afford robots?

Leasing models, like Boston Dynamics’ Spot robot at $5,000/month, are making automation accessible.

Reimagining the American Worker

The debate isn’t jobs vs. robots—it’s about ensuring automation serves people, not replaces them. Without policies that prioritize upskilling and equitable growth, the U.S. risks deepening inequality. As the 2025 election looms, voters must ask: Who benefits from this new industrial revolution?

Your Next Step?

Stay informed on the future of work—subscribe to our newsletter for weekly insights on manufacturing automation jobs and policy.