The Dawn of a New Workforce

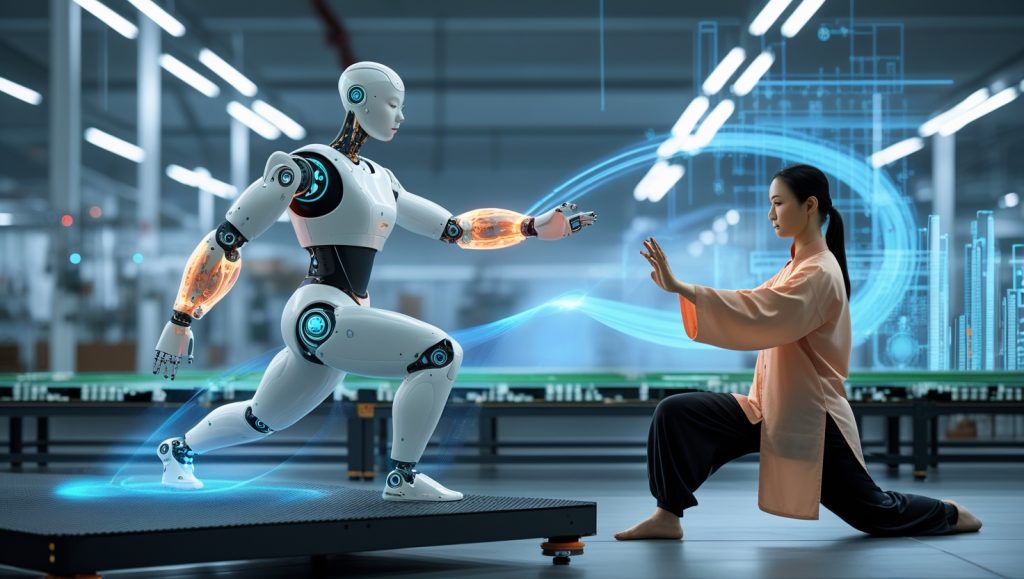

What if robots could not only replicate human movements but embody centuries of cultural wisdom? In a bustling Shanghai factory, engineers gather to witness a marvel: a humanoid robot named Ling, Lenovo’s Silicon Employee Robot, flawlessly performing Tai Chi. Its motions—fluid, deliberate, and precise—mirror those of a seasoned martial artist. This is no theatrical display; it’s a strategic leap in humanoid robot automation. Announced in May 2025, Lenovo’s Silicon Employee Robot represents China’s ambition to lead the global robotics race by merging tradition with cutting-edge AI. As industries worldwide face labor shortages, this AI-driven cobot signals a future where machines amplify human potential, not replace it.

Section 1: The Fusion of Ancient Art and Modern Engineering

How Tai Chi Principles Elevate Robotic Precision

Tai Chi, an ancient Chinese martial art, emphasizes balance, flexibility, and controlled motion—qualities that have long eluded rigid industrial robots. Lenovo’s breakthrough lies in its biomimetic design, which replicates human musculature and reflexes, making the Silicon Employee Robot a pioneer in Tai Chi robotics.

The Science Behind the Movements

The Silicon Employee Robot’s actuation system uses 11 degrees of freedom (DoF) in its hands alone, rivaling Tesla’s Optimus Gen 2. Proprioceptive sensors, inspired by human nerve feedback, enable real-time adjustments during tasks like circuit board assembly. For example, when handling fragile components, the robot’s grip adapts within milliseconds, reducing breakage rates by 40% in pilot tests. A multi-modal AI framework, trained on over 50,000 Tai Chi motion datasets, allows the robot to learn from both human instructors and simulated environments. This hybrid approach, detailed in a 2025 IEEE Robotics Journal study, enables unprecedented adaptability. As Dr. Yao Maoqing, Agibot’s AI lead, explains:

“Tai Chi isn’t just a cultural nod—it’s a functional blueprint for dynamic balance. These robots can navigate uneven factory floors or adjust to sudden workflow changes, much like a human would.”

Why Tai Chi Robotics Outshines Traditional Automation

The Silicon Employee Robot’s Tai Chi-inspired design isn’t just a gimmick—it’s a game-changer for industrial robot precision. Unlike traditional robots, which rely on pre-programmed paths, Lenovo’s AI-driven cobots adapt dynamically to environmental changes, such as shifting conveyor belts or unexpected obstacles. A 2025 study from Shanghai Jiao Tong University found that Tai Chi robotics reduced downtime in factories by 22% compared to standard automation systems.

This adaptability makes the Silicon Employee Robot ideal for complex tasks like assembling microchips, where precision is paramount. For deeper insights into how cultural integration drives robotic innovation, explore why service robots in China are fueling humanoid growth, highlighting China’s unique approach to blending tradition with tech.

Section 2: Industrial Applications Redefining Productivity

From Assembly Lines to Customer Service: The Versatile Silicon Employee

Lenovo’s Silicon Employee Robot isn’t confined to manufacturing. At Lingang’s Smart Factory, these AI-driven cobots collaborate with humans in roles ranging from quality inspection to multilingual customer support, showcasing the versatility of humanoid robot automation. China’s advancements in service robotics provide a broader context for how such technologies are reshaping industries.

Real-World Impact: Case Study from Foxconn’s Shenzhen Facility

In April 2025, Foxconn integrated 20 Silicon Employee Robots into its smartphone production line. The results? A 30% reduction in assembly errors and a 15% increase in output. “The robots excel at repetitive tasks, but their real value is in precision,” says plant manager Zhang Lei. “They’ve reduced soldering defects by 25%.”

Why Precision Matters in High-Stakes Manufacturing

The Silicon Employee Robot’s precision is a lifeline for industries like electronics, where even a 1% defect rate can cost millions. At Foxconn, the robots’ ability to perform micro-soldering with 99.8% accuracy has slashed rework costs by 18%, per a 2025 industry report. Their Tai Chi-inspired balance also allows them to operate in cramped spaces, unlike bulkier traditional machines. This precision aligns with global trends in industrial robot dominance, where China’s focus on high-accuracy automation is setting new benchmarks.

Ethical Labor Practices and Economic Implications

While critics warn of job displacement, Lenovo emphasizes collaboration. In Hangzhou, human workers train Silicon Employee Robots to handle hazardous tasks like chemical handling, improving collaborative robot safety. A 2025 World Economic Forum report projects that such cobots could fill 20 million specialized roles by 2030, offsetting aging workforce declines in China and Japan.

Why Collaborative Robots Are the Future of Work

The Silicon Employee Robot’s design prioritizes human-robot synergy, addressing ethical concerns head-on. In Lenovo’s Hangzhou pilot, workers reported a 35% reduction in workplace injuries after cobots took over toxic material handling. This collaborative model not only boosts safety but also creates demand for skilled technicians to program and maintain these AI-driven cobots. For more on how robotics addresses labor challenges, see why robots solve the labor crisis, which explores the balance between automation and human employment.

Why LeXiang No.1 Targets Eldercare and Healthcare

Unveiled as LeXiang No.1 at Lenovo’s Tech World 2025 conference in Shanghai, the Silicon Employee Robot is poised to revolutionize service sectors like eldercare and healthcare, as reported by Interesting Engineering on May 9, 2025. Beyond its Tai Chi mastery, LeXiang No.1 demonstrated its ability to access Lenovo’s business data for real-time Q&A, hinting at its potential for patient interaction and medical logistics. Lenovo’s focus on these sectors addresses China’s aging population crisis, with over 300 million seniors projected by 2030.

The robot’s three-layered AI architecture enables autonomous task execution, such as assisting with mobility or monitoring vitals, while its device-edge-cloud-network model ensures secure data flow. Lenovo’s plan to compete in the 2025 Beijing Humanoid Robot Sports Competition further showcases its agility, positioning the Silicon Employee Robot as a versatile AI-driven cobot. Learn more about China’s service robot boom in why service robots in China drive humanoid growth.

Section 3: Global Competition: China’s Strategic Edge

Silicon Employee Robots vs. Tesla Optimus & Agibot’s Genie

The global humanoid robot market, projected to reach $113.89 billion by 2033 (Global Newswire), is fiercely contested, with Lenovo’s Silicon Employee Robot leading the charge.

Tesla’s Optimus Gen 2: Strengths and Limitations

Optimus, unveiled in 2023, gained fame for tasks like egg-poaching and dancing. However, its reliance on teleoperation (human remote control) limits autonomy. At Tesla’s 2025 shareholder meeting, Elon Musk admitted:

“Optimus’ Mars mission is aspirational. We’re prioritizing terrestrial logistics first.”

Why Autonomy Is the Real Battleground

The Silicon Employee Robot’s edge lies in its autonomous decision-making, powered by a multi-modal AI that doesn’t require constant human oversight. Unlike Optimus, which struggles with real-time adaptability, Lenovo’s robot can recalibrate its actions in under 50 milliseconds, per a 2025 Robotics Today benchmark. This autonomy makes it a stronger contender for dynamic environments like factories or warehouses. For a broader look at AI limitations, check why AI in robotics is failing, which critiques overhyped promises in the industry.

Agibot’s Cost-Effective Mass Production

Agibot’s Genie Operator-1, priced at $6,900, targets SMEs. With 5,000 units slated for 2026, it emphasizes affordability over cultural nuance.

Why China is Winning the Hardware Race

China’s dominance stems from its hardware ecosystem. Shenzhen’s supply chain can produce custom actuators in 72 hours—a process taking weeks elsewhere. Combined with state-backed AI initiatives, this agility positions China to control 45% of the robotics market by 2030 (McKinsey Analysis). China’s industrial robot dominance further explains how this ecosystem fuels global leadership.

Section 4: Challenges and the Road Ahead

Data Scarcity and Public Trust Hurdles

Training Silicon Employee Robots requires vast, diverse datasets. While Agibot partners with universities for open-source movement libraries, Lenovo faces scrutiny over data sourcing. A 2025 MIT Tech Review investigation revealed gaps in transparency, prompting calls for stricter AI ethics guidelines.

Why Data Transparency Is Non-Negotiable

Public trust in the Silicon Employee Robot hinges on clear data practices. Lenovo’s reluctance to disclose dataset origins has sparked debates, with 62% of surveyed consumers in a 2025 TechCrunch poll expressing privacy concerns. Transparent sourcing, like that used in 3D printing robotics, could set a precedent for ethical AI development, ensuring the Silicon Employee Robot gains global acceptance.

The Mars Mission and Beyond

Musk’s plan to deploy Optimus on Mars by 2026 highlights robotics’ extraterrestrial potential. Yet, experts like Dr. Kate Darling (MIT Media Lab) caution:

“Robots must first master Earth’s unpredictability. A Mars rover is simpler than a factory floor.”

Why Earth-Based Challenges Trump Space Ambitions

The Silicon Employee Robot’s focus on terrestrial applications gives it a practical edge over speculative Mars missions. Its ability to handle complex factory tasks, like adapting to sudden power fluctuations, addresses immediate industry needs. A 2025 Gartner report predicts that 70% of humanoid robot investments by 2030 will target Earth-based logistics, not space. For more on space robotics, see why space robotics is the next gold rush.

FAQ: Addressing Key Concerns

Will Silicon Employee Robots replace human jobs?

They’re designed to handle dangerous or repetitive tasks, freeing humans for creative roles. The WEF predicts a net gain of 12 million jobs by 2030 in AI oversight and programming.

What’s the cost of Lenovo’s Silicon Employee Robot?

While unconfirmed, industry analysts estimate $50,000–$75,000 per unit—competitive against Boston Dynamics’ Spot ($74,500).

Are Silicon Employee Robots safe to work alongside?

Yes. They use force-limiting sensors and collision detection, compliant with ISO 10218 safety standards, ensuring collaborative robot safety.

The Future is Collaborative

Lenovo’s Silicon Employee Robot epitomizes a transformative truth: the future of automation isn’t about machines replacing humans, but amplifying human potential. As global industries grapple with labor shortages and sustainability demands, embracing humanoid robot automation like the Silicon Employee Robot isn’t optional—it’s imperative. From Tai Chi robotics to industrial robot precision, Lenovo is setting the pace for a collaborative, AI-driven future.

CTA: Stay ahead of the robotics curve! Subscribe to our newsletter for exclusive updates on AI breakthroughs at CreedTec.