The Core Takeaway

AGIBOT has launched Genie Sim 3.0, a comprehensive open-source robotics simulation platform built on NVIDIA Isaac Sim. It directly tackles the most expensive bottleneck in industrial robotics—real-world testing—by offering over 10,000 hours of synthetic data, language-driven scene generation, and 1:1 digital twins of industrial environments. This platform isn’t about flashy demos; it’s a practical tool designed to reduce hardware dependence, slash development cycles, and establish standardized benchmarks, accelerating the path from research to reliable factory-floor deployment.

Industrial AI’s Most Expensive Bottleneck: The Need for a New Testing Paradigm

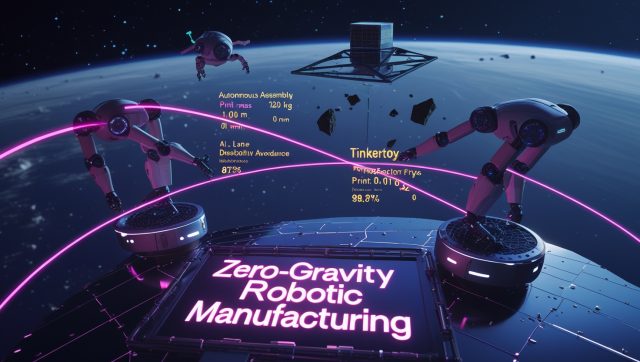

The ambition for intelligent, adaptive robots in logistics, manufacturing, and inspection is universal. The reality, however, has been constrained by a fundamental and costly limitation: how do you thoroughly train and evaluate a robot’s intelligence before it ever touches a factory floor? Physical testing is slow, resource-intensive, and difficult to scale. Every iteration requires hardware, space, and safety oversight, creating a drag on innovation. AGIBOT’s launch of Genie Sim 3.0 at CES 2026 targets this bottleneck directly. It represents a strategic move beyond merely building robots to building the essential infrastructure required to develop robotic intelligence efficiently and at scale .

This release coincides with a broader industry inflection point. As NVIDIA CEO Jensen Huang noted at CES, “The ChatGPT moment for robotics is here,” highlighting breakthroughs in physical AI models that understand and reason about the real world . Concurrently, partners like Siemens and NVIDIA are building “Industrial AI Operating Systems” for adaptive factories . Genie Sim 3.0 enters this landscape as a foundational tool to make such visions testable and achievable, providing the simulated proving grounds where these intelligent models can be refined.

Why Simulation Is No Longer a Compromise for Real-World Performance

Historically, simulation has been criticized for its “sim-to-real” gap—the disconnect between a robot’s performance in a virtual world and its capabilities in the messy, unpredictable physical environment. Genie Sim 3.0 is engineered to close this gap through unprecedented fidelity and data diversity. The platform integrates 3D reconstruction with visual generation, allowing developers to scan real-world locations—from warehouse shelves to assembly line workstations—and convert them into high-fidelity digital assets in minutes .

The scale of its dataset is a core differentiator. AGIBOT provides over 10,000 hours of open-source synthetic data covering more than 200 specific tasks. This dataset isn’t abstract; it’s derived from real-world robot operation scenarios and includes multi-sensor data like RGB-D and stereo vision. By training AI models on this vast, varied, and physically accurate synthetic data, developers can build policies that generalize more effectively to real-world conditions, validating that synthetic data can be a viable substitute under controlled conditions .

Table: Core Components of Genie Sim 3.0

| Component | Description | Key Impact |

|---|---|---|

| LLM-Driven Scene Generator | Creates structured simulation environments from natural language descriptions. | Democratizes environment creation; enables rapid scenario variation. |

| 10,000+ Hour Synthetic Dataset | Open-source data from 200+ real-world tasks with multi-sensor modalities. | Reduces costly physical data collection; provides scale for robust training. |

| Genie Sim Benchmark | Automated evaluation across 100,000+ scenarios, generating performance profiles. | Moves beyond single-metric tests to holistic model assessment. |

| Industrial Digital Twins | 1:1 reconstructions of logistics centers, production lines, etc. | Enables end-to-end testing in true-to-life settings before deployment. |

| Integration with NVIDIA Isaac Sim | Built on the Omniverse-based reference framework. | Ensures high-fidelity physics and access to a robust developer ecosystem. |

From Language to Logic: How LLMs Are Reshaping Robotic Development

Why Natural Language Changes Everything for Developers

A defining feature of Genie Sim 3.0 is its use of large language models (LLMs) as a core engineering tool. Traditionally, creating or modifying a simulation scene required specialized knowledge in coding and physics engines. Now, a developer can describe an environment conversationally: “Create a warehouse picking station with a red bin on the left conveyor and scattered packing materials on the floor.” The system’s Genie Sim Generator interprets this intent, retrieves appropriate assets, and generates the executable code to build the scene in NVIDIA Isaac Sim .

This leap in usability dramatically accelerates prototyping and testing. More importantly, it enables rapid, multi-dimensional generalization. From a single generated scene, the system can use language instructions to spawn thousands of semantic variations—altering lighting, object positions, textures, and clutter—within minutes. This capability is crucial for stress-testing AI models and ensuring they don’t just memorize a specific setup but learn generalizable skills robust to environmental noise .

The Industrial Dataset Advantage: Bringing the Factory into the Simulation

Why Digital Twins Are Critical for Industrial Deployment

While many simulators excel at generic kitchen or living room settings, industrial applications have distinct and often more demanding requirements. AGIBOT claims Genie Sim 3.0 is the first simulation platform to integrate real industrial-scene datasets directly into its training and evaluation pipelines . The platform can reconstruct accurate digital twins of logistics centers, power inspection sites, and automated production lines.

For an engineering manager, this means a new workflow: instead of piloting a costly robot cell on the actual factory floor, the entire system—from the robot’s vision model to its grasping policy—can be developed, validated, and optimized in a virtual replica. This approach significantly shortens algorithm-validation cycles and reduces the upfront capital and risk associated with physical hardware deployments . As one industry observer noted, AGIBOT’s presence at CES, backed by over 5,000 manufactured robots, signals a shift from pure R&D to scaled deployment, and Genie Sim is the tool enabling that transition .

How an Open-Source Robotics Simulation Platform Changes Development Economics

The implications of a platform like Genie Sim 3.0 extend across the entire development lifecycle.

- Cost Reduction: By providing a massive, free dataset and reducing the need for extensive physical “robot hours,” the platform lowers a major barrier to entry for research institutions and startups.

- Accelerated Iteration: Developers can test new algorithms or models in parallel across thousands of simulated scenarios in the time it would take to run a single real-world trial.

- Standardized Benchmarking: The Genie Sim Benchmark, with its 100,000+ scenarios, moves the industry toward a common, rigorous standard for evaluating “embodied intelligence.” This allows for meaningful comparison between different AI models and approaches, which has been a persistent challenge in the field .

“Bringing our full robotics portfolio to CES marks a defining moment for AGIBOT,” said Dr. Yao Maoqing, Partner and President of the Embodied Business Unit at AGIBOT. “It demonstrates our transition from advanced R&D to real-world deployment at scale, while laying the groundwork for an open ecosystem around embodied intelligence.”

This sentiment underscores the strategic thinking: AGIBOT is not just selling robots; it is fostering an ecosystem where its simulation standard could become the benchmark, much like established benchmarks have driven progress in computer vision or natural language processing.

The Open-Source Strategy: Building the Arena to Shape the Game

By releasing all simulation assets, datasets, and evaluation source code as fully open-source on GitHub, AGIBOT has made a calculated bet on community-driven growth . This strategy has several analytical advantages:

- Accelerated Adoption: Researchers and developers can immediately integrate the platform into their workflows without licensing barriers.

- Ecosystem Development: As the community uses and contributes to the platform, it becomes more valuable, attracting more talent and reinforcing its position as a standard.

- Influence on Standards: By providing a comprehensive benchmark, AGIBOT can influence how the industry measures progress in robotics AI, aligning those standards with its own technological roadmap.

This mirrors a broader 2026 trend identified by IBM experts, where competition shifts from the AI models themselves to the orchestration systems and ecosystems that integrate them . AGIBOT is positioning Genie Sim as a key piece of that systems-level infrastructure.

Fictional Anecdote: The Startup’s Advantage

Consider a small startup, “LogiBot AI,” developing a new vision algorithm for parcel sorting. Two years ago, validating their model would have required partnerships with logistics companies for precious real-world testing time—a near-impossible hurdle. Today, they download Genie Sim 3.0, use its digital twin of a standard distribution center, and run 50,000 iterative tests in a week. They can present potential clients not with a prototype, but with a statistically validated performance profile generated by the benchmark. This levels the playing field and accelerates innovation.

Future Outlook: The Simulation-First Development Cycle

Looking ahead, the launch of Genie Sim 3.0 points to a future where a simulation-first methodology becomes the norm for industrial robotics. As digital twin technology and physics-based AI models (like NVIDIA’s newly announced Project Cosmos) continue to advance, the line between simulation and reality will blur further . The platforms that provide the most accurate, scalable, and usable simulation environments will effectively control the gym where the next generation of robotic intelligence is trained.

AGIBOT’s move, combining a serious open-source tool with its own hardware deployments, suggests a pragmatic path forward: the race for useful, deployable industrial robots will be won not just by who builds the best hardware, but by who can most efficiently train and prove the intelligence that operates it.

Frequently Asked Questions (FAQ)

What is the core problem Genie Sim 3.0 solves?

It solves the high cost and slow pace of training and testing AI for physical robots by providing a high-fidelity, scalable simulation environment. This reduces reliance on expensive hardware for development and allows for faster, safer iteration of algorithms .

Is the data in Genie Sim 3.0 relevant for real industrial tasks?

Yes. A key feature is its integration of real industrial-scene datasets, allowing for the creation of 1:1 digital twins of environments like logistics centers and production lines. This ensures models are trained and evaluated on relevant scenarios .

How does the natural language scene generation work?

Using large language models (LLMs), developers can describe a scene in plain English. The system interprets this, retrieves appropriate digital assets from its library, and automatically generates the code to build the scene in the simulator, dramatically speeding up environment creation .

Is Genie Sim 3.0 truly free to use?

Yes. AGIBOT has released the platform as fully open-source. All simulation assets, the over 10,000-hour dataset, and the automated evaluation source code are available on GitHub for developers and researchers to use without cost .

What hardware or software is needed to run it?

Genie Sim 3.0 is built on NVIDIA Isaac Sim, which is based on the NVIDIA Omniverse platform. This requires compatible NVIDIA GPUs and an understanding of the Omniverse ecosystem to run effectively .

Stay Ahead of the Curve in Industrial AI

The transition to simulation-driven robotics development is just beginning. For strategic insights, in-depth market analysis, and actionable intelligence on how these tools are transforming manufacturing, logistics, and automation, subscribe to the CreedTec Insights newsletter.

Subscribe now to get our exclusive analysis on the ROI of simulation platforms and the emerging benchmarks that will define the next generation of industrial robots.

Further Reading & Related Insights

- Lyte’s Visual Brain for Robotics → Complements Genie Sim’s simulation-first approach by highlighting advances in robot perception and vision systems.

- Three Lives of a Robot: Industrial AI → Explores the lifecycle of industrial robots, aligning with how simulation accelerates development and deployment.

- China Robot Simulation Training Field → Provides context on global simulation efforts, reinforcing the importance of high-fidelity training environments.

- Why Domain Randomization in Industrial Robotics Is the Secret Weapon Behind Smarter, More Resilient Automation → Connects directly to simulation strategies for bridging the “sim-to-real” gap.

- Industrial AI Creative Operating System → Broadens the perspective by showing how orchestration systems and platforms integrate with simulation tools for industrial AI.