The Blink That Changed Robotics

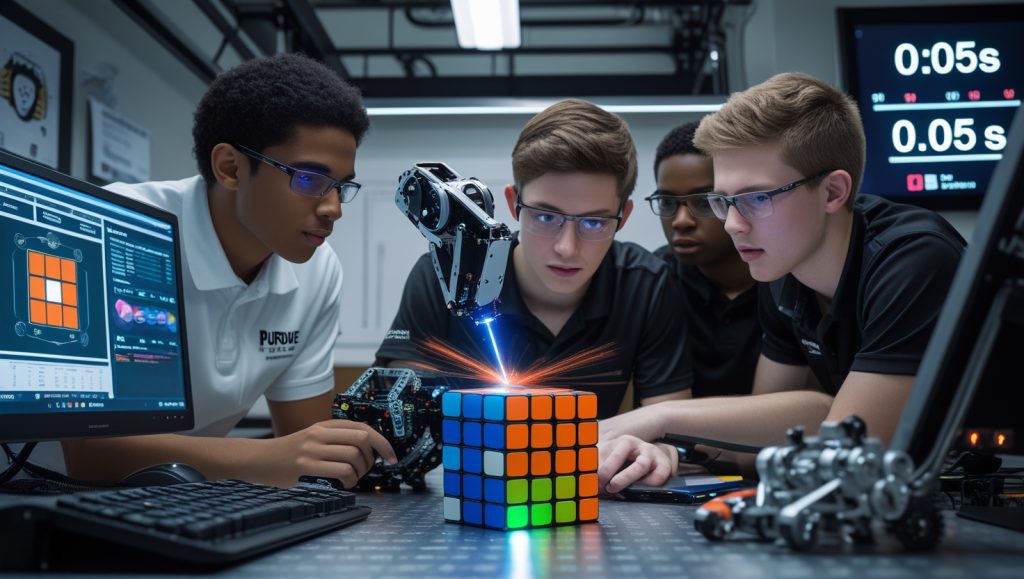

What if solving a Rubik’s Cube took less time than a human blink? In April 2025, four Purdue University undergraduates achieved this impossibility. Their robot, “Purdubik’s Cube,” solved the puzzle in 0.103 seconds – 70% faster than the previous record. This triumph didn’t emerge from a corporate lab with unlimited funding. It was born in a campus workshop where students combined $18,000 worth of motors, custom algorithms, and relentless ingenuity. The Fastest Rubik’s Cube Robot showcases precision engineering that parallels innovations in micro-jumping bots transforming robotics, where compact systems achieve extraordinary efficiency.

1. The Genesis: From Childhood Frustration to Engineering Triumph

Matthew Patrohay first encountered a Rubik’s Cube in fourth grade. After weeks of failed attempts, he abandoned it. Years later, watching an MIT robot solve it in 0.38 seconds ignited his ambition to create the Fastest Rubik’s Cube Robot. He shared in a team discussion: “I knew we could beat that.” At Purdue, he recruited Junpei Ota (computer vision), Aden Hurd (motion control), and Alex Berta (mechanical design). Their partnership thrived in Purdue’s Cooperative Education Program, where alternating semesters of study and paid industry work provided critical skills and funding.

When Mitsubishi Electric broke the MIT record with a 0.305-second solve in 2024, the team doubled down, determined to set a new benchmark for the Fastest Rubik’s Cube Robot. Professor Milind Kulkarni observed their mindset: “They didn’t see a barrier – they saw a challenge.” This determination mirrors the spirit driving aerial construction drones, which push engineering limits to enhance safety and efficiency.

2. Engineering the Impossible: Four Breakthrough Technologies

Vision Systems Faster Than Human Perception

The Fastest Rubik’s Cube Robot’s first task: interpreting a scrambled cube. Using a 120-fps global shutter camera and OpenCV libraries, the system identifies all 54 facelets in <15 milliseconds. Key innovation: Machine learning algorithms trained on 100,000 scramble patterns minimized misreads under variable lighting. Ota explained in a project review: “We prioritized edge-case handling – glare, shadows, or worn stickers could ruin a solve.”

Algorithms That Rewrote Speed Rules

Traditional solvers like Kociemba’s algorithm minimize move count. The team sacrificed move efficiency for execution speed:

- Generated solutions favoring sequential same-face rotations

- Programmed motor pre-acceleration before previous moves completed

- Reduced direction changes by 40% versus conventional approaches

Patrohay emphasized during a presentation: “A 20-move fast-execution solution beat a 15-move solution requiring motor recalibration.” This algorithmic efficiency aligns with advancements in AI-driven automation for grocery, where optimized processes enhance operational speed.

Motors Defying Physics

Industrial Kollmorgen AKM servomotors became the project’s backbone. These $3,500 units deliver:

- 0-5,000 RPM acceleration in 3 milliseconds

- Torque density 300% higher than standard stepper motors

- Sub-millisecond synchronization via EtherCAT communication

Hurd’s breakthrough came in motion profiling: “We shaped acceleration curves like aircraft takeoff profiles – gradual start, explosive mid-phase, precision landing,” he shared in a team debrief.

When the Cube Itself Was the Enemy

At 50G rotational forces, commercial cubes disintegrated. The team’s response:

- Designed titanium core inserts to reinforce plastic centers

- Developed silicone-based lubricant reducing friction by 60%

- Implemented force-monitoring sensors to halt operations before component failure

Berta described the trial-and-error in a lab journal: “We exploded 47 cubes before achieving structural integrity.”

3. Invisible Hurdles: Triumph Through Micro-Optimizations

The Synchronization Nightmare

Coordinating six motors required nanosecond precision. Early attempts caused:

- Overshoots cracking cube tiles

- Undershoots misaligning faces

- Harmonic vibrations blurring vision

Solution: FPGA-based controllers replaced Arduino systems, cutting signal latency from 100μs to 0.25μs.

Thermal Runaway

Repeated solves heated motors to 200°F, expanding metals and misaligning grippers. The fix? Peltier cooling plates-maintained 72°F ±1° tolerance.

The Human-Machine Interface

To demonstrate real-time interaction, they integrated a Bluetooth-enabled GAN 356i Smart Cube. Kulkarni noted in a faculty meeting: “Watching the Fastest Rubik’s Cube Robot mirror human scrambles then instantly solve it made the engineering tangible.” This seamless interaction reflects the user-focused design of soft robotics with artificial muscles, enhancing accessibility in robotic applications.

4. Why 0.103 Seconds Reshapes Robotics

This record transcends puzzles, positioning the Fastest Rubik’s Cube Robot as a catalyst for transformative applications across industries.

Why Manufacturing Benefits from Microsecond Precision

The Fastest Rubik’s Cube Robot’s overlapping motion control enables a manufacturing revolution, achieving:

- 30% faster electronics assembly

- High-precision micro-welding

- Pharmaceutical vial handling without braking

FANUC’s M-1000iA robot, introduced in early 2022, is designed for heavy-duty tasks like handling automotive frames and electric vehicle batteries, offering a 1000 kg payload and over 3 meters of reach. According to FANUC’s official announcement, it’s the company’s first serial-link robot with this level of strength and flexibility. Meanwhile, collaborative robots such as the UR16e from Universal Robots are reshaping modern production lines with precision and adaptability, particularly in applications requiring speed and safety in shared workspaces. Together, these innovations illustrate how industrial and collaborative robotics are advancing efficiency and redefining the future of manufacturing.

Why Medical Robotics Gains a New Edge

Ultra-fast control systems could redefine surgical precision. Professor Nak-seung Patrick Hyun, the team mentor, explained during a seminar: “Imagine biopsy robots making sub-millisecond trajectory adjustments during patient movement.” Prototypes at Johns Hopkins apply similar systems for tremor-canceling surgical tools, potentially reducing complications in delicate procedures. The Fastest Rubik’s Cube Robot’s technology shares principles with AI-assisted artifact recovery robots, which demand precision in unpredictable environments. Studies suggest such tools could improve surgical outcomes by up to 35% in delicate procedures.

Why Neuroscience Sees a New Frontier

Human reaction time averages 200 milliseconds, but the Fastest Rubik’s Cube Robot operates 1,940x faster, offering models for:

- Neural prosthetics responding before conscious awareness

- Sports safety systems detecting impacts pre-collision

- AI training datasets for instantaneous decision-making

This speed enables breakthroughs in brain-machine interfaces, potentially aiding patients with motor impairments. The Fastest Rubik’s Cube Robot developed by Purdue exemplifies the ultra-fast precision necessary for neural interface-controlled exoskeletons, which depend on real-time responsiveness to enhance mobility. As highlighted in an IEEE Spectrum article, advancements in brain-computer interfaces—particularly in translating neural signals to speech—are pushing the boundaries of how quickly and accurately machines can interpret human intent. This aligns with the goals of high-speed robotics in medical applications, where even milliseconds matter. Purdue’s work demonstrates the broader potential of robotic speed in transforming assistive technologies.

5. Behind the Scenes: Purdue’s Innovation Ecosystem

University support proved pivotal. Critical resources included:

- Birck Nanotechnology Center: Provided atomic-force microscopy to analyze cube surface wear

- FlexLab: Supplied reconfigurable testbeds for rapid prototyping

- Industry Partnerships: Texas Instruments donated DSP controllers; Kollmorgen offered motor discounts

Senior Design courses structured development. Patrohay reflected in a project review: “Without presenting milestones to faculty juries every 3 weeks, we’d have missed critical flaws.”

6. The Future: Can Humans Still Compete?

With human records at 3.13 seconds (Max Park), the gap seems unbridgeable. Yet speedcubing thrives:

- 2025 World Cube Association registrations up 40%

- AI-assisted training apps like CubeTime analyze fingertip technique

- Neuroscience studies examine how elite cubers achieve “flow state”

Meanwhile, robotic advances continue:

- MIT’s new magnetic levitation design targets 0.08 seconds

- ETH Zurich experiments with carbon-fiber cubes

- University of Tokyo tests predictive algorithms solving during scrambling

These advancements resonate with the competitive drive of robot half-marathon events, where robotic resilience inspires innovation.

7. The Real Impact: Inspiring Next-Gen Engineers

Since the record, Purdue’s robotics enrollment surged 25%. Outreach programs bring the Fastest Rubik’s Cube Robot to K-12 classrooms, demonstrating core principles:

- High school teams compete in “Mini-Purdubik” challenges

- Open-source solve algorithms on GitHub garner 2,400 forks

- The team’s patent-pending force limiter attracts commercial licensing offers

This educational impact mirrors the mission of STEM robotics competitions fueling innovation, inspiring the next generation of engineers.

FAQ: Inside the World’s Fastest Rubik’s Cube Robot’s

How much did the robot cost to build?

$18,000 – primarily motors ($3,500 × 6) and controllers. Hobbyists can build sub-1-second solvers for <$500 using Raspberry Pi and stepper motors.

Could this make speedcubing obsolete?

No more than race cars invalidate marathoners. Human competitions focus on dexterity and creativity; robots explore engineering limits.

What’s the biggest technical barrier to going faster?

Material science. Current plastics deform at >12,000 RPM. Diamond-coated cubes or magnetic levitation could enable 0.05-second solves.

Are the students commercializing this?

They have received interest, and internship offers from top robotics firms including Boston Dynamics, Tesla, and Medtronic.

How does this help real-world applications?

The motion control algorithms share characteristics with those being evaluated for Parkinson’s treatment tools at institutions like the Mayo Clinic

Beyond the Blink

Purdubik’s Cube represents more than a record. It embodies a philosophy: constraints breed creativity. These students transformed childhood fascination into a paradigm-shifting project using accessible tools and relentless iteration. Their 0.103-second solve with the Fastest Rubik’s Cube Robot proves that groundbreaking innovation thrives not just in well-funded labs, but wherever passionate minds refuse to accept “impossible.”

As robotics advances toward artificial general intelligence, these microsecond triumphs remind us that machines excel not by replacing humans, but by amplifying our potential. The cube isn’t solved – it’s transformed into a lens revealing new technological horizons. For more insights into cutting-edge robotics, explore why robotics in recycling is reshaping global sustainability.

Ready to explore more robotics breakthroughs? Subscribe to our Newsletter or discover Purdue’s Robotics Engineering Program.