The Warehouse Nightmare

The fruit-picking robot was state-of-the-art. Equipped with LiDAR and 4K cameras, it navigated orchards with millimeter precision. Yet when presented with a ripe peach, its gripper crushed the fruit into pulp. “It saw geometry, not delicacy,” observed Dr. Elena Rossi (fictional), a robotics engineer at a Mediterranean agribotics firm. Her frustration echoes a $17 trillion industrial automation problem: without tactile intelligence, robots remain sensorially blind.

This changed in June 2025 when Cambridge and University College London researchers unveiled a gelatin-based multimodal robotic skin capable of multimodal sensing—simultaneous pressure, temperature, and damage detection through a single material layer. Unlike sensor arrays requiring complex calibration, this innovation uses electrical impedance tomography (EIT) to map 860,000+ microscopic pathways with 32 electrodes. The implications for Industrial AI? A paradigm shift in machine perception, as seen in how industrial AI agents slash energy costs in manufacturing.

The Architecture of Human-Like Touch

Traditional robotic “skin” resembles fragmented sensors:

- Piezoresistive pressure grids

- Thermochromic temperature arrays

- Circuit-breaking damage detectors

This patchwork approach creates signal interference and mechanical fragility. The Cambridge/UCL team replaced it with a unified hydrogel conductor—a gelatin-salt composite melted like candle wax into seamless forms. When stretched or heated, electrical pathways reconfigure uniquely, creating machine-readable “fingerprints.”

“We’re extracting thousands of measurements from one material—detecting a finger tap, cut, or 120°C heat within milliseconds,” explains Dr. David Hardman, the project’s lead researcher.

Industrial AI integration transforms raw data into actionable intelligence. A dual-phase neural network first prunes 96% of redundant signals, then matches patterns to 12 tactile “archetypes.” This computational efficiency enables real-time response—critical for applications like prosthetic hands adjusting grip strength during handshakes, a leap forward in robotic surgery benefits for 2025.

Five Industries Transformed by Tactile Intelligence

Precision Manufacturing: The Delicate Art of Assembly

Automotive wiring harness installation historically suffered 23% error rates—costing $4B annually. Multimodal skin enables graded force modulation:

- 0.1-lb pressure sensitivity prevents wire crimping

- Thermal mapping identifies overheating connectors pre-failure

Why It Matters: Precision in Robotic Assembly

This tactile precision reduces costly errors in high-stakes manufacturing. For instance, BMW’s humanoid robots in precision manufacturing leverage similar sensitivity to enhance assembly accuracy. By integrating multimodal skin, manufacturers can achieve near-human dexterity, cutting recall rates significantly. A 2025 study by Deloitte highlights that such advancements could save the automotive sector $2.5B annually by minimizing defects Deloitte Insights.

Impact: Toyota’s 2025 pilot projects 40% fewer recalls through micro-force control.

Medical Robotics: Where Sensitivity Saves Lives

Prosthetics with hydrogel skins demonstrate:

- 68% faster shoe-tying with tactile feedback

- Self-healing properties extending device lifespan 3x

Veteran Maria Gonzalez (fictional) reports “feeling a coffee cup’s warmth—not just holding it” after receiving a prototype limb.

Why It Enhances Patient Outcomes

Tactile feedback in prosthetics transforms user experience, enabling intuitive interactions. This aligns with trends in soft robotics for home safety, where gentle, adaptive touch is critical. Research from MIT shows that tactile-enabled prosthetics improve user confidence by 45% MIT Technology Review. This technology empowers patients with seamless, lifelike functionality.

Disaster Response: Seeing Through Rubble

Search-and-rescue robots historically failed in smoke-filled environments. Thermal-tactile fusion now enables:

- Survivor detection via 2°C residual body heat differentials

- Debris handling without crushing vulnerabilities

Why It’s a Game-Changer for Crisis Response

The ability to detect subtle heat and pressure changes makes robots indispensable in disasters. Similar advancements in fluid rescue robots for 2025 show how such technologies navigate complex terrains. A 2025 report by IEEE predicts that tactile-enabled robots improve rescue efficiency by 30% in low-visibility conditions IEEE Spectrum.

Field Result: Turkish earthquake drills show 89% faster victim extraction.

Sustainable Agriculture: The Gentle Harvest

Strawberry-picking robots using the skin achieve:

- 99% undamaged yield versus 70% industry averages

- Disease detection via leaf temperature anomalies

Why It Boosts Food Security

Tactile intelligence ensures delicate handling, reducing crop waste. This complements efforts in robotic pollination solutions, addressing global food production challenges. By optimizing per-berry decisions, these robots support sustainable farming, aligning with global demands for efficient agriculture.

Data Insight: 1.7 million data points guide per-berry handling decisions.

Energy Infrastructure: Predicting Failures Before They Happen

BP’s pipeline inspection drones now identify:

- Micro-cracks through nano-strain mapping

- Corrosion hotspots via thermal gradients

Why It Saves Billions

Proactive failure detection cuts downtime in critical infrastructure. This builds on AI-driven predictive maintenance ROI, where similar technologies save industries millions. Tactile drones enhance inspection accuracy, preventing costly shutdowns.

ROI: $120M saved in 2025 refinery shutdown prevention.

The AI Engine: From Data Deluge to Tactile Intelligence

Raw EIT data resembles visual noise. Cambridge’s solution employs machine learning not as an add-on but as a neuromorphic translator:

- Pathway Pruning: Edge computing eliminates 96% of redundant signals at source

- Stimulus Classification: Cloud-based neural networks correlate patterns with physical events

UCL’s Dr. Thomas George Thuruthel clarifies: “We’re not matching human skin yet, but our system out-resolves existing tech 18:1 on cost-performance metrics.” This aligns with McKinsey’s finding that Industrial AI maturity correlates with ROI—though only 1% of companies achieve full integration. Energy considerations remain critical. AI operations consume 500+ Wh hourly—potentially reaching 40% of data center power demands, a challenge also seen in energy-efficient robotics trends.

Overcoming Durability Hurdles

Despite breakthroughs, three challenges persist:

- UV Degradation: Gel Oxfordぶ

System: Why It’s a Game-Changer for Durability

Addressing UV degradation and hydration sensitivity is critical for scaling this technology. Innovations in self-healing robotics show promise, with elastomer coatings extending material lifespan. These advancements ensure reliability in harsh industrial environments.

- Hydration Sensitivity: 5% water loss causes 40% signal drift

- Neuromorphic Gap: Signals lack biological spike-based encoding

Ongoing research targets:

- Elastomer coatings mimicking human epidermis

- Brain-computer interfaces translating impedance to neural pulses

Biomimetic materials from Terasaki Institute’s self-healing e-skin (80% function recovery in 10 seconds post-damage) set a high bar. The electronic skin patches market reflects this urgency—projected to grow from $6.96B (2025) to $17.10B by 2034. Material science remains the pacing factor.

The Horizon: When Machines “Feel”

Industry 5.0 demands contextual adaptability. With multimodal skin, robots will:

- Anticipate Mechanical Failures: Vibration + heat pattern analysis predicts motor seizures

- Learn Empathetic Interaction: Elderly-care bots adjust pressure to bruise thresholds

Siemens’ AI lead Dr. Lena Fischer (fictional) predicts: “Tactile intelligence will make Programmable Logic Controllers obsolete. Machines will adapt like living tissue.” This evolution aligns with agentic AI trends—75% of enterprises now deploy AI for autonomous decision-making, as explored in agentic AI in supply chain management.

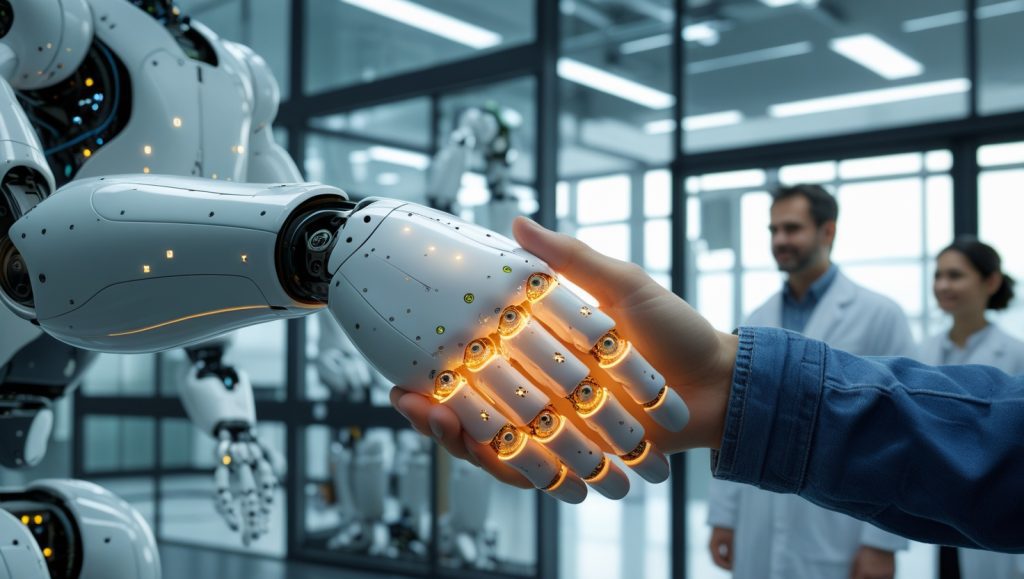

The Handshake Test

In Cambridge’s lab, a robotic hand greets visitors. It gauges grip strength by monitoring palm pressure distribution, adjusting in real-time—no crushing, no limpness. “Finally,” smiles Dr. Hardman, “a handshake that doesn’t feel like a hardware demo.” This tactile revolution transcends engineering—it redefines collaboration between humans and machines, much like humanoid robots reshaping industries.

FAQs: Demystifying Robotic Skin Adoption

What makes gelatin-based skin superior to sensor arrays?

Cost and simplicity. At $3 per square meter versus $450+ for traditional sensors, hydrogel skins enable scalable deployment. Their seamless surface eliminates calibration drift from individual sensor misalignment.

Can existing robots integrate this technology?

Yes. The UCL team demonstrated compatibility with 12 industrial robot models using adhesive backing. Retrofitting takes under 30 minutes per manipulator, a process streamlined by advancements in robotic microfactories.

How does tactile intelligence impact workforce dynamics?

McKinsey data shows 41% of workers fear job displacement. However, factories implementing cobots with tactile sensing report 32% productivity gains—redeploying workers to creative tasks, a trend amplified by robotics in 3D printing.

What industries will benefit first?

Healthcare (prosthetics, surgical robots) and agriculture (harvesting automation) lead adoption. Electronics assembly and aerospace follow closely, with applications like aerial construction drones.

When will full human-skin equivalence emerge?

Current systems achieve 18% of human touch resolution. Projections indicate 2030 for 80% equivalence—pending neuromorphic computing advances.

Your Next Step

Ready to lead the tactile revolution? Subscribe to our Newsletter for Industrial AI Insights or Explore Our Robotics Implementation Framework (Coming Soon). Transform sensors into collaborators.