Disaster relief robot ARMstrong Dex, developed in South Korea, accurately threw a water bottle 10 feet into a barrel—demonstrating critical capabilities for emergency response. Designed for nuclear sites and blocked disaster zones, it combines brute strength (88-pound curls) with precision agility. The test validates its ability to deliver supplies like medical kits or water where humans can’t reach. KAERI’s tech transfer aims to deploy robots in nuclear decommissioning by 2026 — a move similar to ongoing advancements in industrial AI safety compliance in robotics.

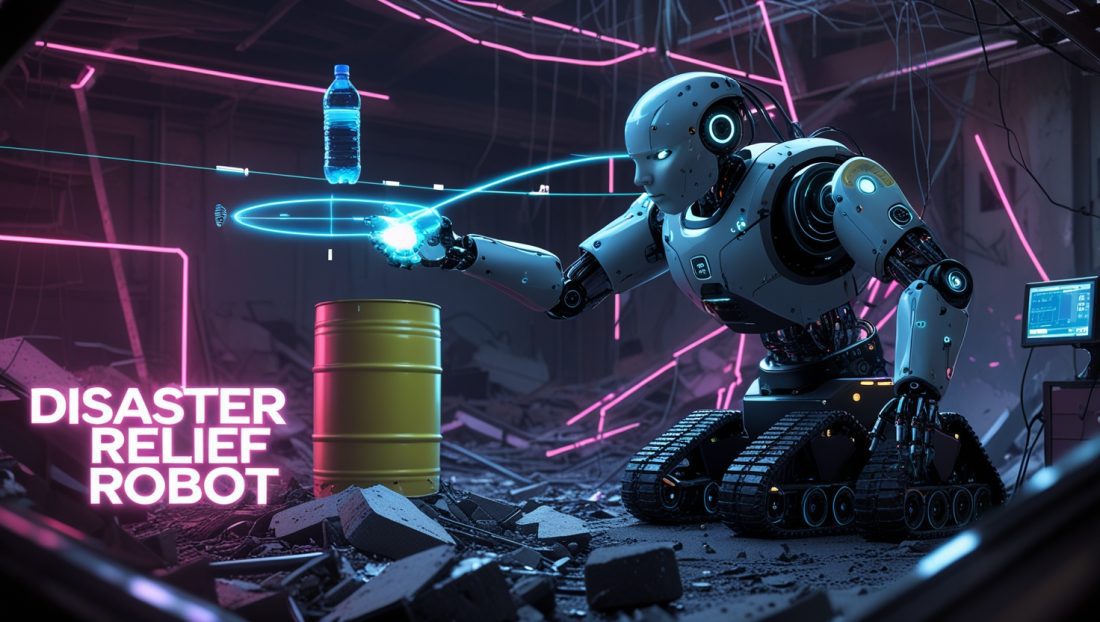

In a 15-second video released on July 28, 2025, South Korea’s disaster relief robot ARMstrong Dex underhand-tossed a 500ml water bottle across a room, landing it perfectly in a yellow barrel 10 feet away. Developed by the Korea Atomic Energy Research Institute (KAERI), this wasn’t a viral stunt but a calculated test of high-stakes agility. For engineers, hitting the target meant proving the robot could deliver life-saving supplies—medical kits, radios, or water—into disaster zones too dangerous for humans, a growing focus area in how hazardous material robots save lives.

The Throw That Changed Disaster Relief Robot Capabilities

The Mechanics of Precision

ARMstrong Dex’s throw required split-second adjustments in trajectory planning, force modulation, and grip control. Unlike static strength tests, throwing demands real-time environmental analysis—factors like distance, object weight, and landing obstacles. KAERI engineers fine-tuned hydraulic systems and motion software during earlier trials (like 44-lb pull-ups and 88-lb arm curls) to achieve this speed-accuracy balance. The complexity of such tests echoes what’s being refined in robotics simulation replacing physical prototyping.

Why Throwing Matters in Disasters

In nuclear facilities or earthquake rubble, direct paths are often blocked. The ability to lob essentials over barriers or into trapped spaces could save lives before rescue teams arrive. As Dr. Lee Soo-hyun, a KAERI robotics lead (quoted in source videos), emphasized: “Every second counts when victims lack water or communication tools. This test ensures our robots don’t just move debris—they deliver hope.” That precision-first mindset mirrors recent developments in AI-driven scientific discovery, where machines must perform under chaotic, real-world constraints.

Beyond Throwing: ARMstrong Dex’s Design Mastery

Table: ARMstrong Dex’s Capabilities

| Feature | Specification | Disaster Application |

|---|---|---|

| Strength | 88-lb single-arm curls, 441-lb deadlifts | Moving rubble, operating heavy valves |

| Mobility | Caterpillar tracks | Navigating debris-filled terrain |

| Manipulation | Dual hydraulic arms with human-like reach | Using tools like fire extinguishers |

| Control | Remote operation from safe distances | Nuclear leak response |

Human-sized proportions let it work in standard corridors and control rooms, while its tracks crush uneven terrain. During a simulated nuclear incident last month, it hooked wires onto terminals and turned safety valves—tasks impossible for wheeled drones. These types of robots mirror humanoid robots used in construction for complex, dangerous environments.

Industrial AI’s Role: From Strength to Agility

From Gym to Rescue Ops

Early tests focused on raw power (e.g., 200kg lifts). But disaster agility requires transitioning between strength and delicacy—like shifting from smashing a door to handing a victim a water bottle. KAERI’s AI-vision systems process spatial data to adjust grip strength and release timing mid-throw. This “dynamic re-targeting” is vital when wind or debris interfere — a common factor in both emergency robotics and computer vision robotics tackling industrial defects.

Nuclear Waste & Beyond

KAERI transferred ARMstrong’s tech to Victex, a nuclear decommissioning firm, for real-world deployment by 2026. Future iterations will map radiation leaks using companion bots like TRAM and RAM. Semi-autonomous mode—where robots interpret verbal commands like “Throw medical kit to third-floor window”—is under the K-Humanoid Alliance’s development. This mirrors the type of autonomous robotics already redefining rescue ops as seen in DARPA’s grand challenges and recent European robotic trials (ARXIV Review).

The Future: Scaling Precision

This test sets a benchmark for rescue robots beyond South Korea. Teams in Japan and the EU are now prioritizing “micro-delivery” skills alongside brute force. As Prof. Elena Rossi (Robotics Institute, Naples) notes: “Throwing seems simple until you need a robot to do it during a typhoon.”

Evergreen Takeaway: Disaster robots must master both might and finesse. ARMstrong Dex’s bottle toss proves that saving lives hinges not just on reaching victims, but precisely sustaining them until help arrives.

Your Next Step

Want more breakthroughs in industrial AI? Subscribe to our Newsletter for exclusive analyses on robotics reshaping nuclear safety, disaster response, and logistics.