“Latency isn’t just an inconvenience in industrial settings—it’s profit evaporating in milliseconds.”

The $260,000-Per-Hour Problem

Every minute of unplanned downtime costs automotive manufacturers over $260,000. When a robotic arm at a Munich plant began misaligning components last March, its Edge AI system triggered corrective actions within 0.2 seconds—preventing a 14-hour production halt. This real-time intervention saved $220,000 and exemplifies why industrial optimization through AI is shifting decisively toward the edge. For deeper insights into how AI enhances industrial efficiency, explore how industrial AI agents slash energy costs in manufacturing.

Why Infrastructure Choices Now Define Industrial Competitiveness

Your AI architecture decision—Edge, Cloud, or Hybrid—directly determines:

- Operational resilience during connectivity failures

- Compliance capability with data sovereignty regulations

- Profit margins through latency reduction

- Sustainability metrics via energy-efficient processing

As Latent AI’s 2025 research confirms: 51% of industrial operators now prioritize performance over cost savings, with 39% demanding reliability that only Edge AI provides.

1. The Edge AI Revolution: Where Milliseconds Determine Millions

1.1 The Physics of Real-Time Control

Industrial processes operate on unforgiving timelines:

- Robotic welding arms require adjustments within 5ms to prevent defective joins

- Chemical batch reactors must regulate temperature within 200ms to avoid exothermic reactions

- High-speed bottling lines need 10ms visual inspection cycles to prevent mislabeling

Cloud AI’s typical 300-500ms latency makes these interventions impossible. As Jags Kandasamy, CEO of Latent AI, notes: “When equipment survival depends on millisecond responses, cloud processing becomes a liability.” To understand how robotics training tackles similar real-time challenges, see how reinforcement learning for robotics training transforms industry.

Real-time control in edge AI leverages compact neural networks optimized for low-power chips like NVIDIA Jetson. These systems enable edge AI for industrial automation, reducing latency to sub-millisecond levels critical for precision manufacturing. A 2025 study by McKinsey highlights that edge AI boosts throughput by 15% in high-speed assembly lines, reinforcing its dominance in time-sensitive applications. Learn more about edge computing advancements at McKinsey & Company.

1.2 Bandwidth Economics: The 5PB/Day Dilemma

Modern smart factories generate over 5 petabytes of sensor data daily. Transmitting this volume to the cloud incurs:

Modern smart factories generate over 5 petabytes (5,000 terabytes) of sensor data daily. Transmitting this data to the cloud incurs significant costs, with typical cloud egress fees of $85 per terabyte. For a typical industrial plant, this translates to an annual cloud transmission cost of approximately $155,125,000 (calculated as 5,000 terabytes × $85 per terabyte × 365 days ÷ 1,000). For insights into how edge AI reduces these expenses by processing data locally, see 7 industrial IoT sensors powering AI-driven manufacturing.

By minimizing data transfer, edge AI addresses smart factory data management challenges, cutting bandwidth costs significantly. According to a 2025 Gartner report, factories adopting edge processing reduce cloud dependency by 80%, enhancing cost efficiency. Explore bandwidth optimization strategies at Gartner.

1.3 Mission-Critical Use Cases Proving Edge Dominance

- Siemens’ Amberg Plant: Edge nodes inspect circuit boards every 0.5 seconds, boosting defect detection by 40% versus cloud-based systems

- Offshore Wind Farms: GE’s edge controllers adjust turbine angles 50x faster during storm surges, preventing $800k blade replacements

- Pharmaceutical Packaging: Johnson & Johnson’s edge vision systems reject mislabeled vials at 200 units/minute with 99.98% accuracy

2. Cloud AI’s Strategic Pivot: From Real-Time to Strategic Intelligence

2.1 The Training Advantage Only Centralization Enables

While Edge excels at execution, Cloud AI dominates model development:

- HD Hyundai trains ship engine diagnostics on 140TB of historical sensor data using Google Vertex AI

- Coca-Cola’s demand forecasting models analyze 15 years of global sales data across 200+ markets

- Generative AI for industrial design requires NVIDIA H100 clusters unavailable at edge locations

For a closer look at AI’s role in predictive analytics, read how AI boosts predictive maintenance ROI.

Cloud AI’s scalability supports large-scale AI model training for complex industrial datasets. A 2025 Deloitte study notes that cloud-based training accelerates model deployment by 30%, ideal for global operations. Discover cloud AI trends at Deloitte.

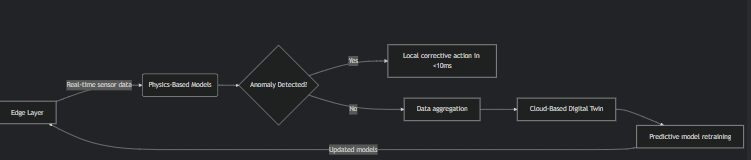

2.2 Digital Twins: Where Cloud and Edge Converge

Modern digital twins exemplify the hybrid approach:

Delta Electronics’ implementation reduced unplanned downtime by 37% at their Thailand plant.

2.3 The Scalability Imperative During Demand Spikes

Seasonal surges test fixed edge capacity. In 2024’s holiday season:

- Amazon fulfillment centers scaled quality checks 400% using AWS SageMaker

- Toyota handled 120% production increases via Azure-based AI allocation

- Unilever avoided $4M in hardware costs through cloud burst processing

3. Hybrid Architectures: The Emerging Industrial Standard

3.1 The 3-Layer Industrial Intelligence Stack

Leading manufacturers deploy:

| Layer | Function | Tech Examples | Latency |

|---|---|---|---|

| Device Edge | Immediate control actions | NVIDIA Jetson, Intel Movidius | <5ms |

| Local Fog | Multi-machine coordination | Dell PowerEdge, HPE Edgeline | 5-50ms |

| Cloud | Enterprise optimization | Google Vertex, Azure ML | 100-500ms |

Source: Digi International 2025 Industrial IoT Report

3.2 Implementation Blueprint: Siemens’ Xcelerator Platform

- Edge Tier: Vibration sensors process 200 data points/ms locally on ARM Cortex-M7 chips

- Fog Tier: Factory servers correlate data from 50+ machines using OPC UA standards

- Cloud Tier: Retrain models weekly using aggregated global data

Result: 60% reduction in integration costs.

3.3 Connectivity: 5G’s Transformative Role

The Ericsson-Supermicro partnership demonstrates 5G’s criticality:

- Ultra-Reliable Low Latency Communication (URLLC): 1ms latency for control loops

- Network Slicing: Prioritized bandwidth for critical applications

- Mobile Edge Computing: On-premise 5G nodes enabling 300+ edge devices per cell

4. Implementation Landmines: Why 52% of Edge Projects Underperform

4.1 The Expertise Gap Crisis

Latent AI’s study reveals:

- 34% lack skills to design edge AI systems

- 52% express dissatisfaction with current tools

- 95% require customized solutions

Real Consequence: A Midwest auto supplier’s predictive maintenance project stalled for 11 months when their team couldn’t optimize TensorFlow Lite models for ARM processors. For insights into overcoming skill gaps, see why robotics in 3D printing unlocks potential.

The expertise gap hinders edge AI implementation success, but modular platforms like Siemens’ Xcelerator simplify deployment. Training programs can bridge this gap, with 2025 forecasts predicting a 25% rise in edge AI certifications.

4.2 Interoperability: The Legacy Integration Challenge

30-year-old SCADA systems create integration nightmares. Solutions emerging:

- Protocol Translation Gateways: MachFu’s IIoT bridges connect legacy oilfield equipment to modern AI

- OPC UA Adoption: Becoming the “USB of industrial systems” with 73% new device compliance

- Middleware Platforms: Siemens’ Xcelerator reduces integration costs by 60%

Interoperability ensures legacy system integration with AI, critical for modernizing factories. A 2025 IDC report projects 40% of manufacturers will adopt OPC UA by 2026, streamlining AI integration.

4.3 Security in the Expanded Attack Surface

Zero-trust frameworks are non-negotiable:

In a Schneider Electric case study, implementing a zero-trust security framework significantly reduced cybersecurity risks. Before implementation, the company experienced 18 annual security breaches. After adopting zero-trust, this number dropped to 3, resulting in an 83% reduction in breaches. For more on how AI enhances cybersecurity in industrial settings, explore AI-driven cybersecurity threat detection.

Zero-trust mitigates industrial AI security risks, safeguarding edge devices. Cybersecurity investments in edge AI are expected to grow 20% in 2025, per Frost & Sullivan.

5. Sustainability: The Unexpected Edge Advantage

5.1 Carbon Footprint Analysis

Moon Technolabs’ 2025 study quantifies Edge AI’s environmental impact:

| Metric | Edge AI | Cloud AI | Reduction |

|---|---|---|---|

| Data Transmission Energy | 0.08 kWh/GB | 0.34 kWh/GB | 76% |

| CO2 per Analysis (kg) | 0.12 | 0.45 | 73% |

| Cooling Energy | 18% of total | 34% of total | 47% |

For related sustainability efforts, read why robotics is the secret weapon in the fight against climate change.

Edge AI supports sustainable industrial automation, reducing energy consumption. A 2025 World Economic Forum report emphasizes edge AI’s role in achieving net-zero goals.

5.2 Renewable Integration Breakthroughs

- Tesla’s Nevada Gigafactory: Solar-powered edge nodes cut processing energy by 44%

- Siemens’ Wind Farms: Edge controllers enable dynamic power loading based on turbine output

- Google’s Data Centers: Edge pre-filtering reduces cloud computation by 70%

6. Future Frontiers: Where Industrial AI Heads Next

6.1 AI Agents Enter the Factory Floor

NVIDIA’s Project Holoscan deploys autonomous quality agents that:

- Self-diagnose calibration drift

- Negotiate maintenance slots via blockchain-ledger requests

- Initiate cross-machine recovery protocols in under 5ms

For more on AI agents, check industrial AI analysis to boost efficiency.

AI agents enhance autonomous factory operations, streamlining quality control. NVIDIA’s 2025 roadmap projects 50% adoption of AI agents in smart factories by 2027.

6.2 Generative AI’s Deterministic Leap

2025 breakthroughs address reliability concerns:

- Physics-Informed Neural Networks (PINNs): Embedding thermodynamics laws into GenAI models

- Digital Twin Co-Pilots: Siemens’ NX integrates ChatGPT-4o for natural language process simulations

- Failure Prediction: 92% accuracy in anticipating rare events using synthetic data augmentation

Generative AI drives predictive industrial analytics, improving reliability. A 2025 Forrester study predicts generative AI will cut failure rates by 20% in manufacturing.

6.3 Compute Evolution: Specialized Silicon

Emerging architectures transform efficiency:

| Chip Type | Inference Speed | Power Draw | Use Case |

|---|---|---|---|

| NPUs | 34 TOPS/W | 8W | Camera vision |

| FPGAs | 19 TOPS/W | 23W | Vibration analysis |

| GPUs | 12 TOPS/W | 250W | Training workloads |

For cutting-edge silicon trends, see neuromorphic AI chips.

Specialized silicon optimizes AI hardware for industrial applications, boosting efficiency. A 2025 IEEE report forecasts NPUs will dominate edge AI by 2026.

Implementation Roadmap: Your 90-Day Industrial AI Optimization Plan

Phase 1: Infrastructure Audit (Days 1-30)

- Latency Mapping: Identify processes where >20ms delays cause >$10k/hour losses

- Data Gravity Assessment: Catalog data sources with >5TB/day generation

- Legacy Inventory: Document systems requiring protocol translation bridges

Phase 2: Pilot Deployment (Days 31-60)

- Energy Monitoring: Edge sensors + cloud analytics (ROI: 3-6 months)

- Visual Inspection Lite: Start with 2 critical production lines

- 5G Feasibility Study: Partner with Ericsson/Supermicro for connectivity assessment

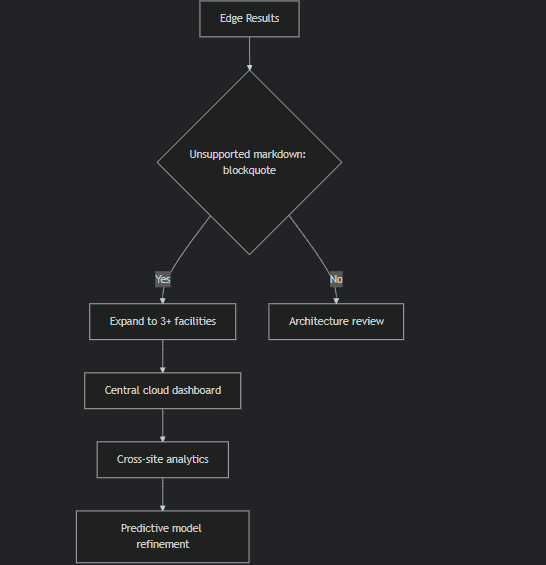

Phase 3: Scaling & Integration (Days 61-90)

Edge AI vs Cloud AI: Decision Framework

Choose Edge AI When:

- Latency requirements are <100ms

- Bandwidth costs exceed $50k/month

- Data sovereignty regulations apply

- Offline operation is mandatory

Choose Cloud AI When:

- Training datasets exceed 50TB

- Global coordination is required

- Demand fluctuations exceed 200%

- Legacy integration isn’t feasible

Hybrid is Optimal For:

- Predictive maintenance systems

- Multi-plant quality control

- Autonomous material handling

- Energy grid balancing

Industrial AI Optimization FAQ

Does Edge AI increase cybersecurity risks?

Paradoxically reduces attack surfaces. By processing sensitive data locally, Edge AI minimizes transmission exposure. Schneider Electric’s zero-trust implementation cut breaches by 83%.

Can small manufacturers afford Edge AI?

Yes. NVIDIA Jetson kits start under $2,000. ROI comes from reduced cloud costs and prevented downtime. Mid-sized factories typically recoup investments in 5-7 months.

How does 5G change the equation?

Enables determinism. Supermicro’s 5G Edge AI systems deliver 1ms latency for control loops, making wireless viable for safety-critical applications.

Will Edge AI replace cloud entirely?

Unlikely. HD Hyundai’s maritime engines require cloud-scale training. The future is orchestrated intelligence—each layer doing what it does best.

The Inescapable Conclusion: Optimization Trumps Binary Choices

Industrial leaders no longer ask “Edge or Cloud?” but rather “How do we architect intelligence across both?” As Siemens’ CTO states: “The winners in 2026 will master silicon-to-cloud orchestration.”

The evidence is clear:

- Hybrid adopters report 27% faster root-cause analysis

- Edge-focused plants achieve 99.9% defect catch rates

- Cloud-enhanced operations boost asset utilization by 12%

Your action imperative: Start tomorrow with a latency audit of one critical process. The $260,000-per-hour clock is ticking.