The Silent Factory Revolution

Walk through BMW’s Leipzig plant today, and you’ll notice an eerie quiet. Safety cages have vanished. Instead, Figure Robotics’ humanoids maneuver alongside technicians, handling 1,000 precision part placements daily without fatigue. This isn’t science fiction—it’s 2025’s manufacturing reality, driven by Industrial Robotics Leaders like Figure Robotics and ABB. Their AI-driven orchestration represents the most significant industrial transformation since Henry Ford’s assembly line. To understand how AI enhances precision in such settings, see how 2025 computer vision robotics crush defects to dominate industry.

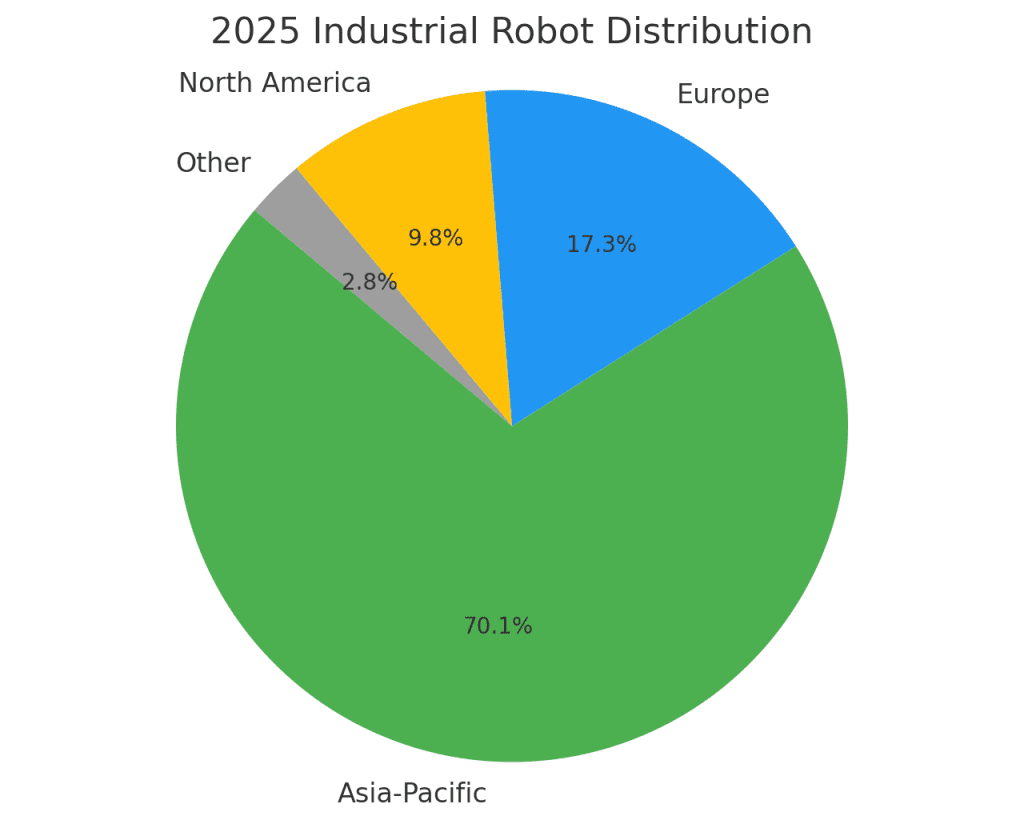

The data reveals an irreversible trajectory:

- 4.28 million industrial robots now operate globally—a 10% year-over-year surge

- Asia dominates 70% of new installations, with China alone accounting for 51%

- The market will explode from $55.1 billion in 2025 to $291.1 billion by 2035, growing at 18.1% annually

Behind this transformation stand five Industrial Robotics Leaders—engineering powerhouses redefining productivity.

1. ABB Robotics: The AI-Integrated Systems Architect

Core Innovation: Swiss precision merged with industrial AI. ABB’s robots function as self-optimizing production neurons, leveraging real-time data to anticipate failures and refine operations.

Transformative Applications:

- TruePick vision systems process sensor data 30× faster than human reflexes, enabling micron-level defect detection in Volkswagen’s EV factories

- Predictive maintenance algorithms reduce automotive production downtime by 40%, analyzing vibration patterns from 200+ sensors per production line

- SafeMove 3 technology enables human-robot collaboration with <100ms collision response times, eliminating traditional safety barriers

Real-World Impact: At Siemens’ Amberg facility, 120 ABB bots achieve 99.99988% accuracy in circuit board assembly—a defect rate 50× lower than manual processes. This precision stems from ABB’s integration of IoT sensors, which feed real-time data to AI systems for instant adjustments. A Deloitte study on smart factories highlights how IoT-driven automation is transforming manufacturing by enhancing quality control and reducing product defects.. For more on IoT’s role, check top 7 industrial IoT platforms for smart factories.

2. FANUC: The Precision Engineering Powerhouse

Market Position: With 750,000+ global installations, FANUC dominates high-stakes manufacturing through relentless reliability and precision engineering.

AI Breakthroughs:

- Deep Learning Welding Toolbox enables self-calibrating weld paths that adapt to material inconsistencies in real-time

- Zero-Downtime Architecture predicts motor failures 72 hours in advance, slashing unplanned stoppages by 60%

- FIELD System Ecosystem connects 34,000+ devices in Toyota’s factories, creating self-optimizing production networks

Industry Benchmark: FANUC’s M-2000iA/2300 Super Heavy Payload Robot handles 2,300kg payloads with 0.02mm repeatability—critical for aerospace structural assembly. This reliability is key in aerospace, where precision prevents costly errors.

A McKinsey report on predictive maintenance highlights how AI-driven automation is helping manufacturers reduce equipment downtime by 30–50%, with some implementations reporting even higher gains. These findings align with claims from industrial leaders like FANUC, which emphasize predictive maintenance as a cornerstone of smart factory efficiency—minimizing disruptions and extending machine life through real-time diagnostics and proactive servicing.Learn how AI enhances such systems in why predictive maintenance AI leads factory efficiency in 2025.

3. Yaskawa Motoman: The Cobot Revolution Catalyst

Strategic Differentiation: Japanese engineering excellence focused on accessibility. Their MotoMINI holds the title of world’s smallest industrial robot yet delivers enterprise-grade precision.

Technical Advancements:

- AI-Assisted Welding with real-time seam tracking adjusts for thermal distortion during high-speed automotive production

- 3D Vision-Enabled QC Systems reduce electronics assembly defects by 99.97% through microscopic anomaly detection

- Predictive Motor Analytics extend operational lifespans by 7,000+ hours, cutting total ownership costs by 18%

SME Adoption Case: Over 63% of Yaskawa’s 75,000+ deployments serve companies with under 500 employees, democratizing automation. For more on accessible robotics, see why robotics in 3D printing unlocks potential.

4. KUKA Robotics: The Human-Robot Collaboration Pioneer

Innovation Legacy: German engineering redefining shared workspaces. The LBR iiwa remains the first ISO-certified collaborative robot.

Intelligence Leaps:

- 7-Axis Force Sensitivity detects contact under 0.1N—gentler than a butterfly’s landing—enabling delicate medical device assembly

- KUKA.Connect IIoT Platform analyzes 1.4 million data points per minute for real-time process optimization

- AI Path Optimization reduces automotive painting cycle times by 18% while cutting material waste by 23%

Collaboration Benchmark: At Bosch’s Dresden semiconductor plant, KUcluA cobots work within 12 inches of technicians, boosting output by 34% without safety incidents. This safety record relies on advanced AI ensuring seamless human-robot interaction. A Forbes Technology Council article explores how collaborative robots (cobots) are transforming shared workspaces by enhancing efficiency, safety, and precision. Explore human-robot collaboration further in why robot behavior influence boosts industrial AI in 2025.

5. Universal Robots: The Cobot Democratization Leader

Disruptive Model: Danish design philosophy making automation accessible. The UR20 cobot consumes just 200 watts—less than a PlayStation—while lifting 20kg payloads.

Market Transformation Drivers:

- No-Code Programming via touchscreen interfaces reduces deployment time from weeks to hours

- UR+ Ecosystem offers 300+ certified components for plug-and-play application switching

- Lease Pricing at $5/hour eliminates capital barriers for small manufacturers

Global Impact: Universal Robots’ installations grew 400% in developing economies since 2023, enabling automation adoption in regions facing severe labor shortages. For more on automation’s global reach, read why China’s industrial robot dominance is reshaping global manufacturing.

The Intelligence Engine: AI’s Role in Modern Robotics

Generative Process Optimization

ABB’s Ability Studio creates optimal work paths in 3D simulations, reducing automotive workcell footprints by 15% while maintaining output.

Swarm Intelligence Networks

Amazon’s 1,000-bot warehouses coordinate via hive-mind algorithms, reducing package retrieval times from 90 to 22 seconds. For insights into swarm intelligence, check ways humanoid robot swarm intelligence.

Self-Healing Mechanics

KUKA’s predictive maintenance prevents 92% of bearing failures by analyzing ultrasonic signatures months before audible symptoms emerge.

Hardware Revolution

Neuromorphic chips like Intel’s Loihi 2 enable 100× faster decision-making with 10% the power consumption of traditional processors, allowing real-time adaptation to production variables. Learn more about neuromorphic advancements in neuromorphic AI chips.

Global Automation Geography: The New Industrial Map

Regional Dominance Drivers:

- China’s $3.65B robotics market fuels electronics megafactories producing 80% of global smartphones

- Germany’s robot density reaches 415 units per 10k workers—triple the global average—driving automotive innovation

- U.S. reshoring initiatives spur 14.9% CAGR growth as companies like Tesla automate battery production

Investment Surge: Amazon’s $1B Industrial Innovation Fund backs 12 humanoid robotics startups targeting warehouse deployment by 2026. For more on humanoid robotics, see humanoid robot economics driving 38b industry growth by 2035.

Cobot Revolution: Economic and Operational Realities

Collaboration Breakthroughs:

| Parameter | Traditional Robots | Collaborative Robots |

|---|---|---|

| Deployment Time | 8-14 weeks | 4-48 hours |

| Payload Range | 100-2,500kg | 3-20kg |

| Average ROI Period | 42 months | 9 months |

| SME Adoption Rate | <12% | 63% |

Sector Transformation:

- Pharmaceuticals: Stäubli’s cleanroom cobots handle vaccine vial packaging with 0.1μm precision, doubling throughput

- Food Processing: Omron’s AI-bots pack 4,200 sushi boxes/hour without human contact, eliminating contamination risks

- Construction: Hyundai Robotics’ automated welders reduce high-rise structural assembly time by 70%

Implementation Challenges: Navigating Automation’s Realities

Cybersecurity Vulnerabilities

Manufacturing breach attempts surged 47% (2023-2025), with ransomware attacks crippling auto plants for weeks. Honeywell’s quantum-safe encryption now protects robotic networks. For more on cybersecurity, explore AI-driven cybersecurity threat detection master.

Workforce Transition

While automation displaces 20 million roles, it creates 65 million higher-skill positions. Germany’s “AutoChance” program retrains auto workers as robot technicians in 12 weeks.

AI Bias in Quality Control

Training data gaps cause $14B in false rejects annually. Blockchain training ledgers now audit decision trails, reducing biased rejections by 82%. Learn how blockchain enhances trust in blockchain-verified reforestation fixing carbon credit fraud.

Future Horizons: The 2030 Automation Landscape

Quantum Robotics

Google and Honeywell’s joint project enables 1,000× faster calculation speeds for real-time production optimization, launching 2027.

Bio-Hybrid Actuators

MIT’s artificial muscles using genetically engineered tissues promise 300% efficiency gains over electric motors by 2028. For more on bio-hybrid tech, see biohybrid insect technology 2025s unstoppable force.

Self-Replicating Lunar Factories

NASA’s Project Artemis deploys KUKA swarms that 3D-print solar arrays using moon regolith, targeting 2032 operational capability.

Market Projections:

- Humanoid robots claim 12% market share by 2030 (Figure, Apptronik)

- AI-as-a-Service platforms dominate 43% of robotics software revenue

- Edge intelligence adoption cuts cloud dependence by 78% in hazardous environments

Strategic Imperatives for Industry Leaders

The robotics revolution isn’t approaching—it’s actively unloading at your dock. As Boston Dynamics’ Stretch robots autonomously unbox themselves in warehouses, and Neura Robotics’ MAiRA systems make autonomous decisions, intelligence becomes industrial currency.

Companies hesitating face existential risk:

- Automotive laggards see production costs 37% higher than automated rivals

- Electronics manufacturers without AI-QC experience 8× higher recall rates

- SMEs rejecting cobots face 68% longer time-to-market for new products

As Prof. Hiroshi Ishiguro of Osaka University Robotics Institute observes, the critical question is how to ethically deploy these systems, reskill workforces, and build sustainable abundance.

Disclaimer: This article includes forward-looking statements and industry projections based on current trends. Claims and statistics may reflect emerging data; verify with primary sources before acting.

Industrial Robotics FAQ

Can SMEs afford industrial robotics without massive capital investment?

Yes. Robot-as-a-Service (RaaS) models now dominate 41% of cobot deployments, with leases from $5/hour. Universal Robots’ pay-per-use programs show 9-month average ROI.

How do modern robots address energy sustainability concerns?

Regenerative drives in FANUC models capture braking energy, reducing consumption by 35%. ABB’s sleep modes cut idle power use by 95%—equivalent to 14,000 households’ annual savings. For more on energy efficiency, check top 7 energy-efficient robotics trends transforming industries in 2025.

What human roles emerge as robots handle repetitive tasks?

Demand for robot technicians (+142%), AI trainers (+89%), and collaboration designers (+76%) outpaces traditional roles. Siemens retrained 92% of displaced workers for these positions.

How quickly can production lines integrate collaborative robots?

UR’s no-code systems deploy in 4-48 hours. Standard Bots’ RO1 achieves full operational integration in under 6 hours using drag-and-drop programming.

The Automation Mandate

Industrial robotics in 2025 transcends mere machinery—it represents an operational philosophy blending human ingenuity with machine precision. The leaders profiled here deliver more than metal and code: they provide adaptable partners that learn, optimize, and elevate human potential.